5/13/25

What You Need To Know About Diamond-Coated Styli

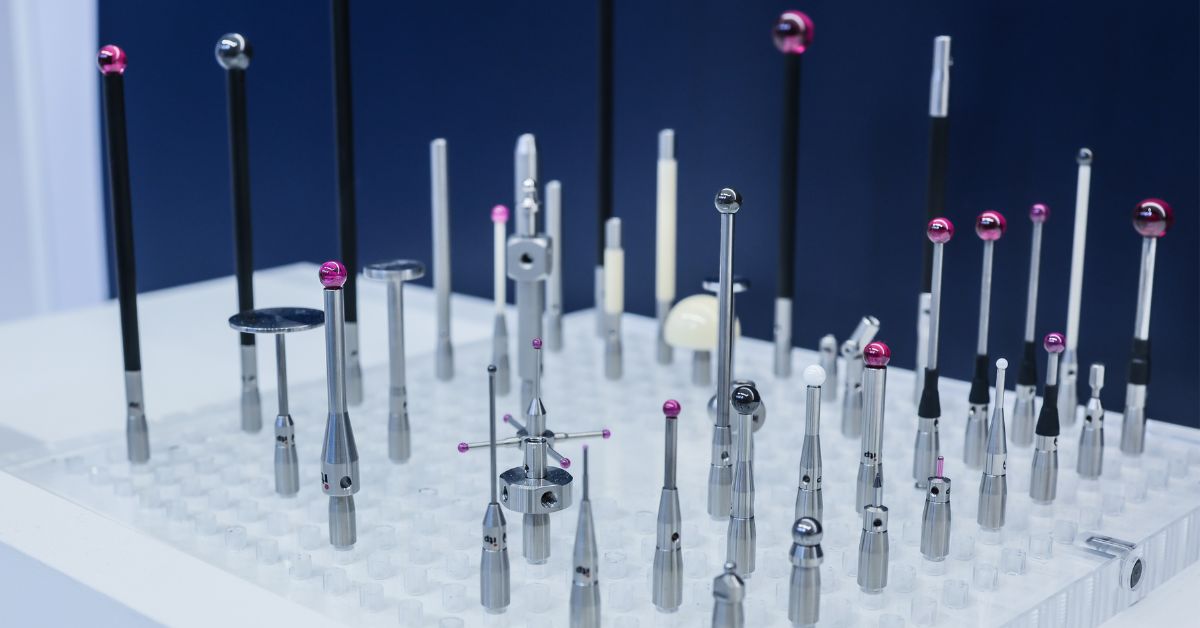

When you’re taking measurements of products and parts in manufacturing, challenges often arise in environments where materials are abrasive, components are intricate, and precision is essential. In such demanding scenarios, even the most advanced coordinate measuring machines (CMMs) can falter without the right tools.

Diamond-coated styli can tackle these obstacles head-on. Combining exceptional durability with unparalleled accuracy, these styli excel where others wear down. If you’re curious about the innovation driving this performance, this guide covers what you need to know about diamond-coated styli and why they’re reshaping how we measure the world around us.

What Are Diamond-Coated Styli?

Diamond-coated styli are precision tools used in CMM applications to measure and inspect parts with the utmost accuracy. They are crafted with a solid base material such as tungsten carbide or ceramic, which is then coated with an ultra-thin layer of industrial-grade diamond. This diamond coating significantly enhances the stylus’s performance, especially when compared to traditional ruby-tipped styli.

The industrial-grade diamond coating provides an exceptional level of hardness, resistance to wear, and smoothness. These properties allow for superior measurement precision, even in demanding applications like inspecting rough surfaces or abrasive materials. Ultimately, diamond-coated styli are engineered to deliver lasting reliability in harsh manufacturing environments.

Key Benefits of Diamond-Coated Styli

Why should you consider diamond styli for your CMM operations? Here are the standout advantages that make them a game-changer for manufacturing professionals.

1. Unmatched Wear Resistance

The diamond coating provides incredible wear resistance, extending the life of the stylus. Unlike ruby-tipped styli, which can wear down when measuring abrasive materials like aluminum or cast iron, diamond-coated styli maintain their integrity for far longer.

2. Reduced Material Build-Up

One of the main challenges with other types of styli is the material transfer during measurements. For instance, when inspecting aluminum parts, residue can build up on the stylus tip, leading to inaccuracies. A diamond surface resists such material accumulation, ensuring consistent and reliable measurements.

3. Enhanced Precision

Thanks to the smooth surface of the diamond coating, diamond-coated styli minimizes friction during contact with surfaces, resulting in highly accurate measurements.

4. Cost Efficiency

While the initial investment in diamond-coated styli may be higher, their longer lifespan and lower maintenance costs make them an economically sound choice in the long run.

Applications Where Diamond-Coated Styli Shine

Diamond-coated styli are not a one-size-fits-all solution, but they thrive in specific scenarios, adding significant value in various industries.

Rough and Abrasive Surfaces

When measuring components made from abrasive materials, such as cast iron or powdered metals, diamond-coated styli excel. They resist the wear and tear that can quickly degrade standard ruby options.

Aluminum and Non-Ferrous Metals

As mentioned before, ruby-tipped styli will experience aluminum buildup when in use. Diamond-coated styli prevent this issue and maintain accuracy and efficiency.

High-Precision Components

For industries such as aerospace, automotive, and medical manufacturing, where precision is non-negotiable, diamond-coated styli deliver exceptional reliability. For instance, the electronics and semiconductor industries have increasingly smaller and more delicate parts that require precise styli, like diamond-coated options.

How To Choose the Right Diamond-Coated Stylus

Selecting the correct diamond-coated stylus for your application involves understanding specific requirements and matching them with the stylus’s features. Here’s what you should consider:

1. Material Being Measured

Evaluate the properties of the material you’ll be measuring. For abrasive and soft, non-ferrous materials, a diamond-coated stylus is an optimal choice.

2. Stylus Size and Shape

Consider the design of the stylus. A ball-tip stylus is ideal for standard point measurements, whereas a disc-shaped stylus may suit groove and feature measurements.

3. Compatibility With Your CMM

Ensure the diamond-coated stylus you select is compatible with your CMM machine’s specifications and software.

4. Manufacturer Reputation

Purchase your diamond-coated styli from a trusted manufacturer, like itpstyli, which specializes in high-quality CMM accessories and offers customer support for technical inquiries.

Maintenance Tips for Diamond-Coated Styli

To maximize the lifespan and performance of any stylus, maintenance is non-negotiable. Here are a few regular maintenance tips you’re going to want to follow:

- Check your stylus for signs of wear or damage before each use, especially if you’re measuring abrasive materials.

- Use a soft, lint-free cloth to clean the stylus tip. Avoid harsh cleaning agents that might compromise the diamond coating.

- Store your styli in protective cases to prevent accidental damage and contamination when not in use.

- Check the mounting of the stylus to ensure secure attachment and proper alignment. Loose or misaligned styli can result in inaccurate measurements and damage to your equipment.

- Even the most durable stylus requires periodic calibration to ensure consistent performance and precision.

Common Myths About Diamond-Coated Styli

Diamond-coated styli are often surrounded by misconceptions that can lead to improper use or unrealistic expectations. Understanding the facts behind these common myths will help you make the most of this advanced measuring tool.

1. “Diamond Styli Are Too Expensive To Justify the Cost.”

While diamond-coated styli may have a higher upfront cost, their durability and low maintenance requirements lead to substantial long-term savings.

2. “They’re Only for Specialized Applications.”

While diamond-coated styli are indispensable for specific applications, their versatility makes them a valuable option for standard measurement tasks, especially if you want to minimize maintenance.

3. “They Don’t Need Regular Cleaning or Calibration.”

Despite their exceptional durability, regular cleaning and calibration are still crucial to maintaining their peak performance.

Why Invest in Diamond-Coated Styli?

For professionals in fields such as automotive, aerospace, and manufacturing, diamond-coated styli are invaluable tools that boost precision, efficiency, and ROI. They are built to withstand demanding environments and are ideal for applications requiring consistent accuracy over time.

When you invest in diamond-coated styli, you're ensuring quality and reliability in your measurements. This type of styli represents the gold standard in metrology.

By now, you’ve learned what you need to know about diamond-coated styli and their invaluable role in achieving precise and reliable measurements. If quality, durability, and consistency are your priorities, Itpstyli is your trusted partner. Not only do we offer industry-leading diamond-coated styli, but we also provide customization services tailored to meet your specific applications and expectations.

Don’t compromise on accuracy—choose Itpstyli to take your measurement solutions to the next level. Explore our range today and experience the difference that itpstyli can make in the precision of your CMM applications.