Reach new dimensions

itpstyli provides replacement styli of all thread sizes for all standard CMM systems. We also offer a complete line of accessories for the probe systems of all leading manufacturers in the world.

Latest technologies yield superior quality

With its enormous range of choice the itpstyli product line is one of, if not the largest available in North America. From thread sizes M2 through M6, we are prepared to ship the product you need from our inventory on the same business day (orders by 3 pm central time).

Should you have a special request, we welcome the opportunity to manufacture your custom stylus.

In order to achieve the best results for you, we produce our styli with state of the art production and assembling technologies. This includes sophisticated 10-axis CNC turning and milling as well as CNC grinding, which enables us to produce complete parts in one “clamping.” This accounts for the superior precision of our products. New technologies in laser cutting and welding are adding to the quality of our products, along with a final touch of special, high-precision assembling techniques.

Certified quality

In order to guarantee the reliability of our products, we manufacture our styli to ISO 9001 certified standards. This means that all of our production, assembly, material management, and gluing techniques are subject to strict and continuous quality control – from cleaning through final assembly.

We offer much more in addition to certifications and guarantees…

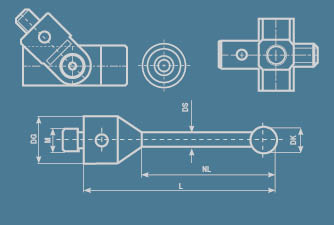

Peg-mounted styli

Most companies today offer a peg-mounting option only for high-precision calibration standards. Conventional probes generally have the probe ball glued to a collar, thus increasing the likelihood of the ball breaking away.

itpstyli provides peg-mounted and drilled probe balls as small as 0.3 mm as a standard offering. Our peg mounting technology provides increased mechanical strength, thus reducing ball breakaway. Proprietary drilling and bonding technologies allow us to provide ruby, silicone, and zirconium balls that have a blind hole, epoxied and mounted on a peg.

We also use the latest technologies for high-precision collar mounting for ball sizes below 0.3 mm, thus ensuring long-term stability.

Light-weight and rigid styli and probe combinations

Conventional probes are made of solid metal, which makes them difficult to configure, depending on the application.

At itpstyli, we supply only lightweight probes or complete probe combinations in lightweight, adjustable-mass configurations. This allows you to design the probe configuration and mass precisely to your measurement task and sensor technology.

We laser weld our styli to ensure maximum rigidity at the joints of complete probe configurations, which are made from materials such as titanium or carbide. By using highly complex, but comparatively lightweight probe configurations, you need to change probes less often, thus reducing change-out and calibration time.

The choice is yours – nothing but the best materials

Our line of products gives you maximum flexibility. In addition to probe stems made from standard materials such as stainless steel, carbide, ceramic and carbon fiber, we offer probe stems made of titanium tubes and TEMP-COMP, an enhanced carbon fiber with thermal-stable properties that compensates for temperature deviations in uncontrolled measuring environments.

Click here for more information on product materials and technical data.