12/22/25

What Thread Pitch Do I Need for My Probe Head?

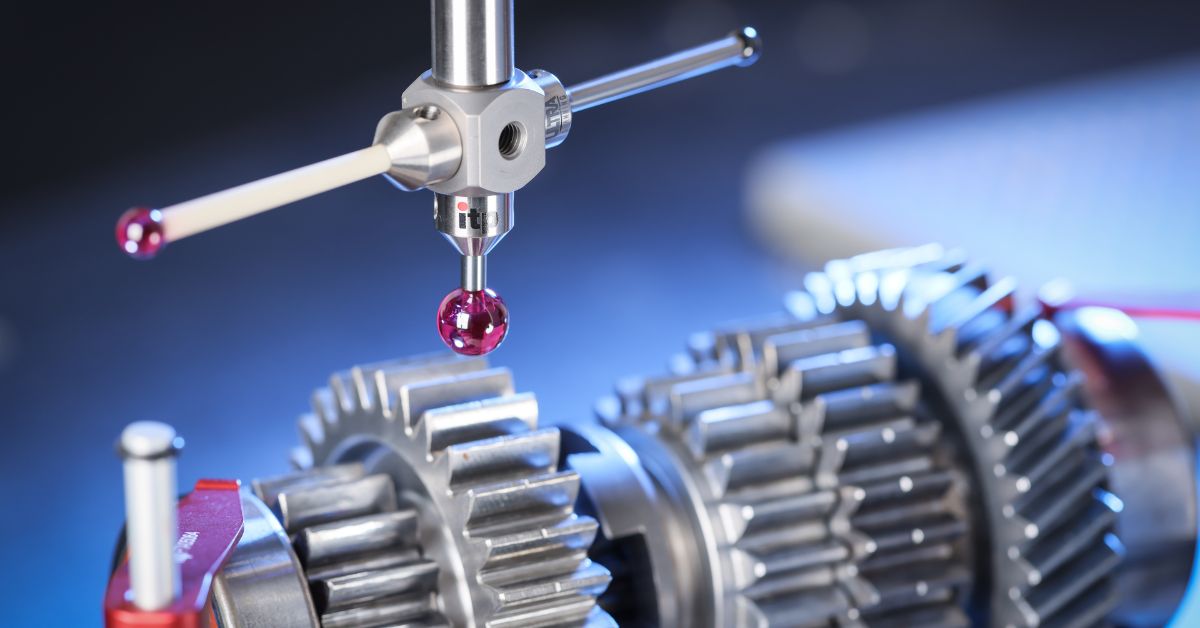

When you’re manufacturing parts, the smallest details decide whether a part passes inspection or stalls production. One of those details I the threads that connect your probe head to its stylus.

Figuring out the thread pitch you need for a probe head is less about trial and error and more about understanding the standards that drive accuracy across several industries. The right pitch ensures replacements lock in seamlessly and keeps your inspection process running without interruption.

What Is Thread Pitch?

Thread pitch, in the context of CMM and machine tool styli, refers to the size and spacing of the helical threads that connect a stylus to a probe head or sensor. Standards define both the diameter and the spacing of these threads.

Choosing the correct pitch is critical. It keeps the stylus securely attached and reduces vibration. Even more so, the correct pitch prevents inaccurate readings and protects the fine threads on both the stylus and the probe head. Because thread pitch is a universal specification, components from different manufacturers can work together seamlessly.

Common Thread Standards in Probe Heads

Most modern CMMs and machine tools use a standardized set of metric thread sizes for their styli and probe heads. These are commonly referred to as M2, M3, M4, and M5. Each "M" number corresponds to the nominal outer diameter of the thread in millimeters.

M2 Thread (2mm Diameter)

The M2 thread is one of the most widely used standards, especially for touch-trigger probes on CMMs. Its small size makes it ideal for applications requiring access to small features and for general-purpose inspection tasks. You will find a vast array of styli available with an M2 thread, including simple ball styli, star styli, and disc styli. Its prevalence makes finding a replacement or a specialized configuration straightforward.

M3 Thread (3mm Diameter)

The M3 thread offers a step-up in robustness compared to the M2. It provides a more rigid connection, which is beneficial when using longer styli or heavier configurations like star clusters. This added stability helps minimize deflection and vibration during measurement, leading to more consistent results. M3 threads are common on both touch-trigger probes and some scanning probes, where greater stiffness is a priority.

M4 Thread (4mm Diameter)

Moving to an M4 thread provides even greater strength and rigidity. This standard is frequently used for demanding applications, particularly in machine tool probing systems. Probes on CNC machines often face harsher conditions than those in a CMM lab, and the M4 thread’s durability stands up to the challenge. It supports very long extensions and large, complex stylus arrangements without compromising measurement integrity.

M5 Thread (5mm Diameter)

The M5 thread is the largest and most robust of the common standards. It is primarily used for high-precision scanning probes where maximum rigidity is essential. Scanning applications are sensitive to any form of deflection, and the solid connection of an M5 thread minimizes these effects. This standard is also used for specialized gear measurement probes and other applications that require large, heavy stylus systems.

How To Identify the Thread Pitch You Need

Determining the correct thread pitch for your equipment can be done through several simple methods.

Check Your Probe Head Manual

The most reliable source of information is the official documentation for your probe head or sensor. The manufacturer’s manual will explicitly state the required thread specification for mounting styli. This document removes all ambiguity and is the first place you should look when you are unsure.

Inspect Existing Styli

If you have styli that are already in use with your probe head, they can provide the answer. Many styli have their thread size engraved or printed on the stem. Look for markings like "M2" or "M3" near the threaded end. If there are no markings, you can use a thread gauge or calipers to measure the thread diameter and determine its size.

Consult Supplier Catalogs

Reputable suppliers provide detailed catalogs that list styli by their thread size. These resources are often organized to make it easy to find compatible components. You can browse sections dedicated to M2, M3, M4, or M5 styli. If you need assistance, a knowledgeable customer service team can help you identify the correct product for your specific probe head model.

Industry-Specific Considerations

Different industries have unique measurement challenges, which can influence the choice of thread pitch.

Medical Manufacturing

The medical device industry often deals with small, intricate components with tight tolerances, such as implants and surgical instruments. M2 threads are prevalent here because small-diameter styli are needed to access tiny features. The lightweight nature of M2 styli is also beneficial for minimizing probing force on delicate parts.

Aerospace Components

Aerospace components, such as turbine blades and structural airframe parts, demand a combination of high accuracy and robustness. While M2 and M3 threads are used for smaller parts, M4 threads are common for inspecting larger components where longer styli and extensions are necessary. The rigidity of the M4 connection helps maintain accuracy over these greater lengths.

Electronics Manufacturing

In electronics manufacturing, components are getting smaller and more densely packed. Measuring features on printed circuit boards (PCBs) and micro-housings often requires extremely fine-tipped styli. M2 threads are the standard, as they support the smallest and lightest styli needed for these delicate, high-precision tasks.

Automotive Industry

The automotive industry uses a wide range of probing applications, from engine block inspection to body panel analysis. M3 and M4 threads are widely used to provide the stiffness needed for scanning large surfaces and measuring heavy components. The durability of these larger threads is well-suited to the high-volume, automated measurement environments common in automotive production.

Quick Purchasing Guide

Once you know the thread pitch you need, sourcing the right styli is a straightforward process.

Online Catalogs

The fastest way to find a replacement stylus is through a comprehensive online catalog. Look for suppliers who offer a wide selection of in-stock items. With thousands of styli available, you can filter by thread size, tip material, and stylus type to quickly locate the exact component you need. A well-organized catalog, like itpstyli’s, makes it possible to find and order a same-day CMM probe stylus to minimize operational interruptions.

Custom Solutions

Sometimes, a standard catalog item won't meet the needs of a unique measurement challenge. In these cases, a custom stylus solution may be the answer. Itpstyli can work with you to design and manufacture a stylus tailored to your specific application, material, and thread requirements. This ensures you have the perfect tool for the job.

Choosing the right stylus or accessory isn’t just about availability. It’s about confidence in every measurement you take. When you know the thread pitch you need for a probe head, you remove uncertainty from the process and ensure your inspection tools perform exactly as intended. That clarity is what keeps production lines moving and reinforces trust in the results your team delivers.