5/16/25

What Is a CMM Stylus and How Does It Work?

From aerospace to medical care, countless industries rely on exact measurements to ensure quality, functionality, and safety. At the heart of this precision lies the Coordinate Measuring Machine (CMM) and its indispensable component, the stylus.

What is a CMM stylus, and how does it work? Explore the significance of this small yet essential tool and how it delivers the precision that modern industries demand. Learn everything you need to know about CMM styli, including their components, types, and the science behind their operation.

What Is a CMM Stylus?

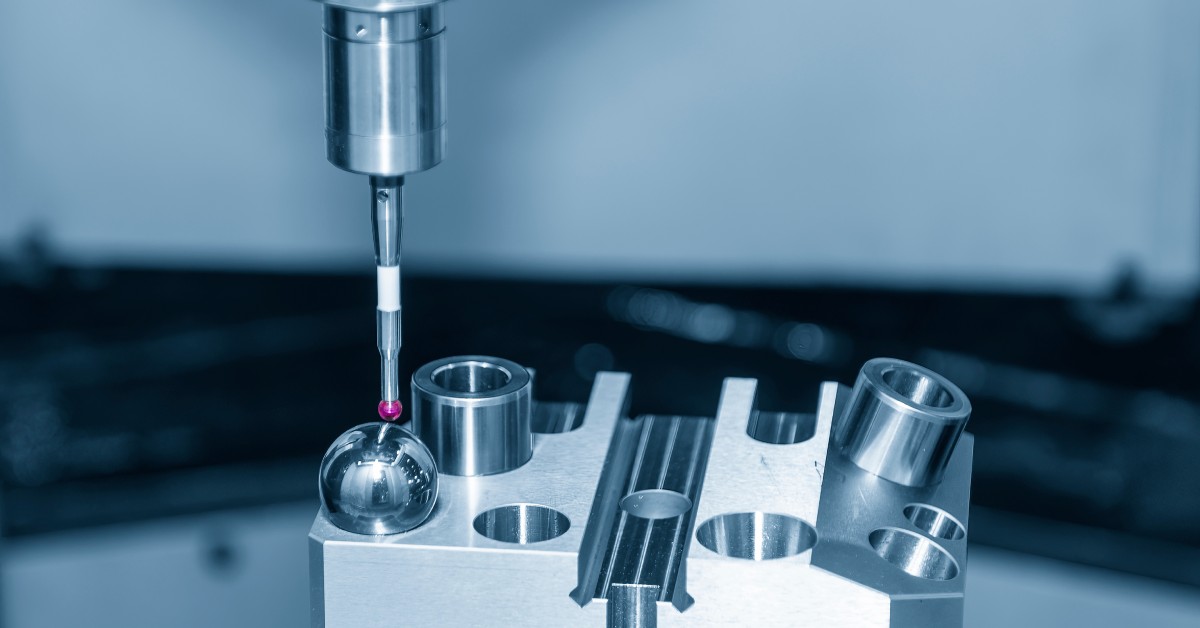

A CMM stylus is the precise measuring tool attached to the CMM probe, which interacts with the surface of the object being measured. Whether you're inspecting the dimensions of an engine part or validating the intricacies of a mold, the stylus serves as the point of contact that translates physical surface data into actionable measurements.

The stylus's primary function is to gather real-world 3D coordinates by physically touching or scanning the surface of an object. The CMM then processes these coordinates to assess whether the component meets specifications. Choosing the correct stylus for your CMM is vital because small discrepancies in design, material, or tip shape can create measurable impacts on the accuracy of your results.

Key Components of a CMM Stylus

Understanding the anatomy of CMM styli helps clarify how it performs its role with such precision. A typical CMM stylus consists of three main components.

Stylus Tip

The stylus tip is the crucial element that makes contact with the surface of the part being measured. It’s commonly crafted from ruby, silicon nitride, or zirconia due to the materials’ durability and low wear. The material must maintain a smooth surface to ensure accurate measurement over time. This is important to minimize wear and tear despite frequent usage.

Stylus Shaft

The shaft connects the tip to the probe and must be extremely rigid to prevent measurement errors caused by bending or vibration. Manufacturers use materials such as stainless steel, carbon fiber, and ceramic for their light weight and excellent strength.

Stylus Thread

This is the connector between the shaft and the CMM probe itself. While it might seem straightforward, the thread's precision is critical to ensure a seamless fit and alignment with the CMM probe. Even the slightest misalignment here could distort results.

How Does a CMM Stylus Work?

The functionality of a CMM stylus lies in its ability to bridge the physical and digital worlds. When the stylus tip touches a workpiece's surface, it registers the contact point's spatial coordinates. Sensors within the CMM probe detect this interaction, sending signals to the system's software.

The software then processes these signals into 3D data, forming a map of the component’s dimensions. CMM styli are effective because of their ability to maintain consistent contact or scanning accuracy. Even the smallest shifts or imperfections in a component are measurable. A CMM stylus is the foundation of ensuring reliable dimensional inspection.

Types of CMM Styli and Their Applications

Different tasks and surfaces demand different stylus designs. Choosing the right type ensures both accuracy and efficiency.

Straight Styli

The most common type, straight styli, are used for general measurements on flat or curved surfaces. Their versatility makes them an excellent starting point for standard operations.

Cylinder Styli

These are ideal for scanning surfaces or edges where consistent contact is necessary across a specific line or area. Cylinder styli are particularly effective in inspecting circular or cylindrical components.

Disk Styli

For measuring grooves, recessed features, or similar intricate parts, disk styli are a reliable choice. Their unique design allows the tip to reach areas that straight or cylinder styli simply cannot.

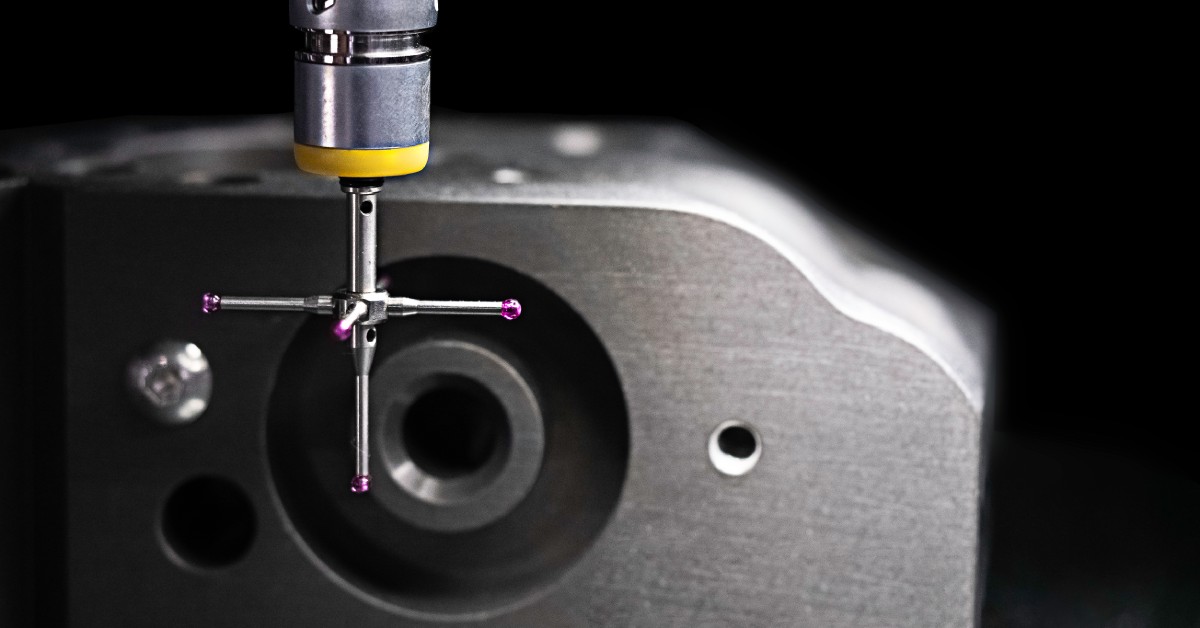

Star Styli

Star styli feature multiple tips radiating from a central hub, making them invaluable for inspecting complex geometries where access from multiple angles is necessary. This is common in the automotive and aerospace industries.

Hemispheric Styli

Best suited for sensitive or delicate surfaces, hemispheric styli distribute contact pressure evenly, reducing the risk of damaging or deforming the material being inspected.

Factors To Consider When Choosing a CMM Stylus

As you can see from the many types of styli, one might be better suited for your needs over another. Several considerations come into play to ensure compatibility with your specific application:

- Material compatibility: Ensure the stylus tip material matches the surface being measured to avoid issues like scratching or premature wear.

- Environmental conditions: Consider factors such as temperature variations and vibrations within your facility. Certain materials, like carbon fiber shafts, are better suited for high-accuracy operations in variable environments.

- Measurement requirements: Analyze what level of precision is required for your specific task and choose a stylus that delivers on those needs without compromising efficiency.

- Application complexity: Specialized parts may call for custom-built styli designed to meet unique inspection challenges.

Maintenance and Best Practices for CMM Styli

Despite their robust design, CMM styli require consistent care for optimal performance. Here are some key tips for maintaining your styli:

- Periodically inspect your stylus tip for signs of wear, scratches, or damage. Even minor imperfections can distort measurements.

- Use a microfiber cloth and an approved cleaning solution to remove dirt or debris that may accumulate on the tip.

- Store your unused styli in designated protective cases to prevent damage.

- Ensure your CMM is calibrated regularly to account for any potential stylus misalignments.

- Select a stylus with adequate rigidity for your application to prevent bending and ensure long-term reliability.

Experience the Best Quality With Itpstyli CMM Styli

At itpstyli, we pride ourselves on offering premium quality and custom CMM styli designed to meet your precise measurement needs. By choosing our products, you're investing in durability, accuracy, and performance that you can rely on for every application.

Our extensive range ensures you'll find the perfect stylus for your specific requirements, supported by expert customer service to guide you every step of the way. Experience the difference of expertly crafted styli that enhance your CMM's capabilities—shop with itpstyli today for unmatched quality and precision.

Understanding what a CMM stylus is and how it works is key to unlocking the true potential of your coordinate measuring machine. By selecting the right stylus, you're ensuring accurate measurements, optimizing efficiency, and enhancing the overall performance of your CMM.

You can trust itpstyli’s expertise in providing you with the right CMM stylus for your needs. And if you still can’t find what you need in our collection, we’re happy to work with you to create a custom stylus that delivers the results you need. Empower your operations with precision tools that make a measurable difference in accuracy.