5/16/25

Tips for Choosing the Right CMM Styli Products

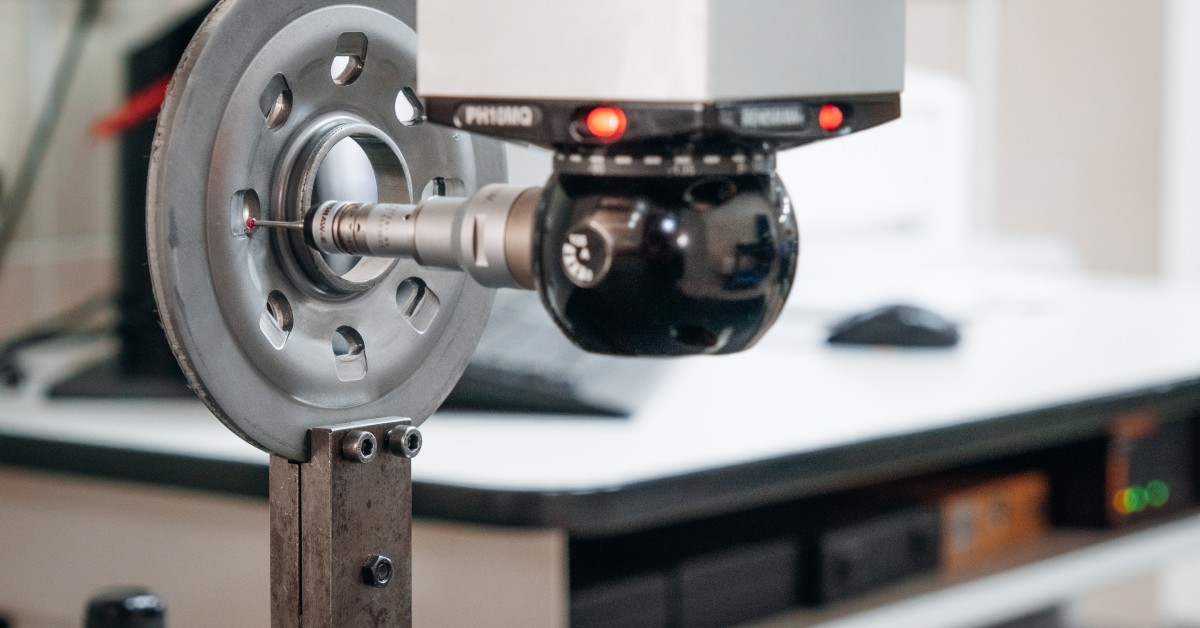

The accuracy of your coordinate measuring machine (CMM) depends heavily on one critical component: the stylus. Working with the right stylus is key to ensuring precise measurements, maintaining quality control, and preventing costly errors.

Whether you're in aerospace, automotive, or manufacturing, finding the right stylus for your application ensures the accuracy of your measurements. Consider how our practical tips for choosing the right CMM styli products can help you achieve exceptional results and keep your operations running smoothly.

Understand the Basics of CMM Styli

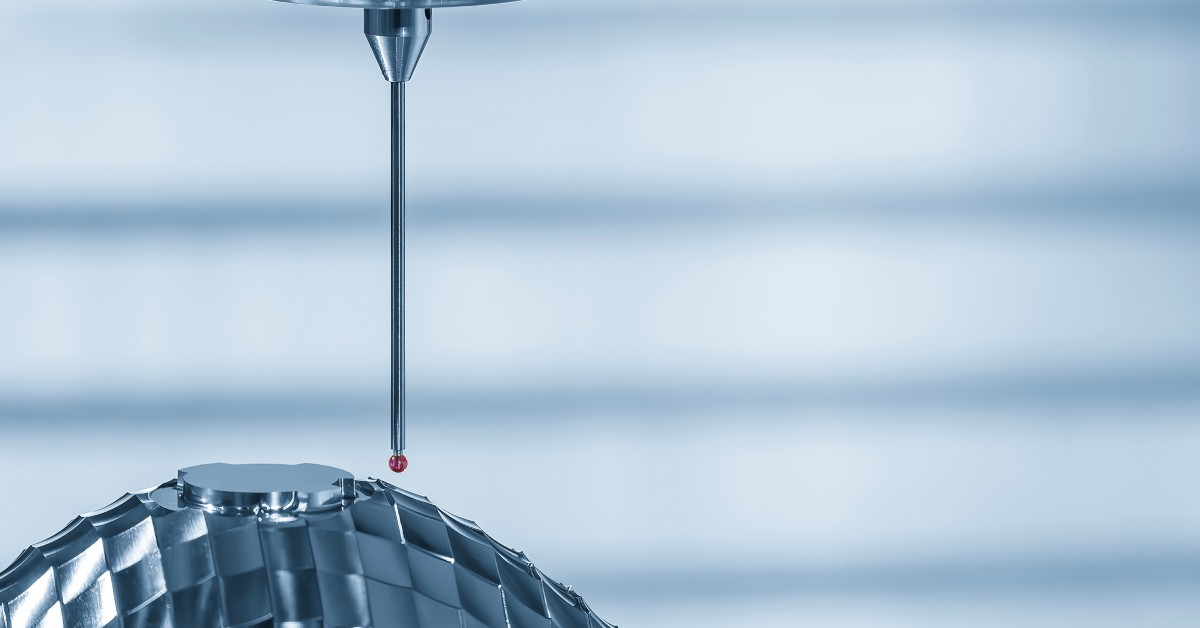

CMM styli are the crucial components that physically touch the surface of the part being measured. Their role is to interact with the material, collect data points, and transfer that information to the coordinate measuring machine for evaluation. A typical CMM stylus is made up of three key parts:

- Stylus tip: The tip is the contact point for measurements. This part is chosen to suit specific characteristics of the material being inspected.

- Stylus stem: This connects the tip to the base and provides the necessary length for various applications. It needs structural integrity and rigidity to ensure precise measurements without deflection.

- Stylus base: The base attaches the stylus to the CMM probe and often varies depending on the stylus type.

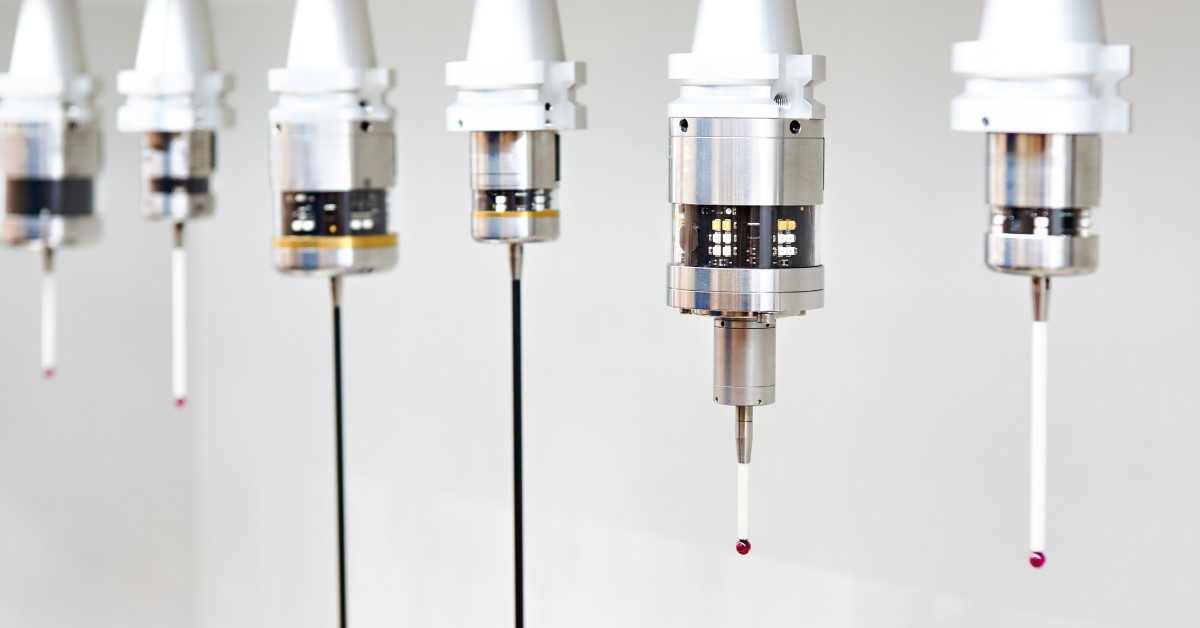

Types of Styli Available With itpstyli

At itpstyli, we proudly offer an extensive range of styli to suit nearly every CMM application. Whether you’re measuring intricate components or larger machinery, our products are expertly designed to deliver precision and reliability. Here’s an overview of the styli we carry:

- Straight styli

- Stepped-stem styli

- Conical base styli

- Threaded-stem styli

- Stepped-base styli

- Stepped-base, stepped-stem styli

- Non-threaded pin styli

- Non-threaded, stepped-stem pin styli

- Extended-thread styli

- Extended-thread, stepped-stem styli

- Pointer styli

- Other straight styli

Key Factors To Consider When Choosing CMM Styli

When choosing the right CMM stylus for your application, several key factors come into play. Carefully evaluating these aspects ensures optimal performance and measurement accuracy for your operations.

Material of the Stylus Tip

Each stylus tip material is specifically designed to address unique measurement needs, ensuring precision and reliability in various applications. Here's a closer look at their ideal uses.

Ruby

Ruby tips are popular for general-purpose use across many scanning applications due to their excellent hardness and smooth surface. However, they are best utilized in less abrasive environments and are not recommended for scanning soft materials like aluminum, where material transfer could impair accuracy.

Silicon Nitride

This material is highly effective in applications involving aluminum. Its non-stick properties significantly reduce aluminum adhesion, ensuring consistent performance and cleaner scans. This makes silicon nitride tips perfect for industries dealing with aluminum components.

Zirconium Oxide

Known for its outstanding durability, zirconium oxide is ideal for aggressive scanning tasks or when measuring hard, wear-prone materials. Its resistance to wear ensures long-lasting performance, even in environments where standard tips might degrade quickly.

Diamond Coated

Diamond-coated tips stand out for challenging measurement scenarios. Their extreme wear resistance makes them suitable for high-precision tasks in abrasive environments, such as scanning rough surfaces or materials like glass and composites.

Carbide and Ceramic

While less frequently used, these materials excel in specific applications. Carbide offers robustness and is often used in industrial settings requiring high-impact scanning. Ceramic, on the other hand, resists thermal expansion and is ideal for temperature-sensitive applications where maintaining accuracy is a priority.

Material of the Stylus Stem

The stylus stem material is critical in ensuring accuracy, durability, and performance during measurement processes. Each material has unique properties, making it suitable for specific applications.

Carbon Fiber

This material is exceptionally lightweight, making it ideal for long styli, where maintaining rigidity with minimal deflection is essential. Additionally, its low thermal expansion ensures consistent performance in varying temperature conditions, making it a top choice for precision tasks in dynamic environments.

Carbide

Known for its rigidity and high strength, carbide is best suited for shorter styli used in high-precision tasks requiring minimal vibration and maximum stability. This material is favored in scenarios where heavy-duty measurement is needed without sacrificing accuracy.

Stainless Steel

Offering a balance of stability and cost-effectiveness, stainless steel is a versatile option for general-use applications. It provides good rigidity and is durable. Stainless steel is practical for environments that do not require extreme precision or lightweight materials.

Ceramic

Ceramic stems are ideal for specialized applications where lightweight properties are critical, but the material must also resist bending and breakage. Additionally, ceramic stems are non-magnetic and corrosion-resistant, making them suitable for sensitive or highly technical tasks.

Stylus Shape and Size

The shape and size of the stylus tip should match the intricacy and size of the component you’re measuring. Straight styli, for example, works best for most basic applications, while specialized shapes like stepped-stem or pointer styli are designed for more unique geometries.

Application-Specific Needs

Finally, consider the specific demands of your application. Delicate parts may call for lightweight styli, while harder-to-reach areas may require extended-thread or stepped-stem styli. The application dictates the stylus’s ideal length, diameter, and strength.

Common Mistakes To Avoid When Selecting CMM Styli

While selecting a stylus may seem straightforward, there are common pitfalls that can compromise your results. Here are a few mistakes to avoid:

- Ignoring material compatibility: Using the wrong tip material for your component can lead to rapid wear, inaccurate measurements, or surface damage to the part.

- Choosing the wrong length: Overly long styli can cause deflection, while shorter ones may not reach all necessary points.

- Disregarding calibration needs: Using a variety of styli without proper recalibration may compromise your CMM’s accuracy.

- Overlooking application-specific requirements: Not taking unique measurement challenges into account can lead to inefficiencies and errors.

Careful attention to detail can prevent these issues and keep your CMM operations running smoothly.

Stay Updated on CMM Technology

CMM technology evolves rapidly. Staying informed about the latest advancements ensures you’re always using the best tools available for your production and quality assurance needs. Manufacturers like itpstyli are constantly innovating, offering enhanced materials, designs, and custom-styli options to improve precision and efficiency.

Consider itpstyli for Your Stylus Needs

Choosing the right CMM stylus impacts your operation’s overall efficiency and accuracy. Partnering with a trusted supplier like itpstyli ensures you have access to top-tier styli, extensions, and accessories backed by decades of experience and expertise.

By following our tips, you’ll save yourself time, money, and effort while achieving exceptional results. Our extensive inventory and commitment to innovation make us the clear choice for all your stylus needs. Contact us today to explore our product range and find the perfect styli for your applications.