8/7/25

The Pros and Cons of Coordinate Measuring Machines

Coordinate measuring machines (CMMs) have transformed precision manufacturing and quality control, enabling industries to achieve exceptional accuracy in dimensional measurement. These advanced tools have redefined quality assurance and production validation, delivering unmatched precision that is vital in fields like aerospace, automotive, and medical device manufacturing. However, as groundbreaking as this technology is, it comes with both compelling advantages and notable challenges.

Understanding the pros and cons of coordinate measuring machines is crucial for manufacturing professionals evaluating their potential impact on their operations. Up-front costs, operational efficiency, and long-term benefits can determine whether a CMM is the right investment for your organization. By weighing these considerations carefully, business leaders can make informed decisions to enhance their manufacturing processes and quality standards.

Key Advantages of CMMs

Unparalleled Precision

CMMs deliver measurement accuracy that surpasses traditional manual inspection methods by significant margins. These machines routinely achieve accuracy levels within micrometers, which enables manufacturers to meet high quality standards of their respective industries. The precision capabilities extend beyond dimensional measurements to include complex geometric tolerances, surface profiles, and intricate part geometries that would be impossible to verify manually.

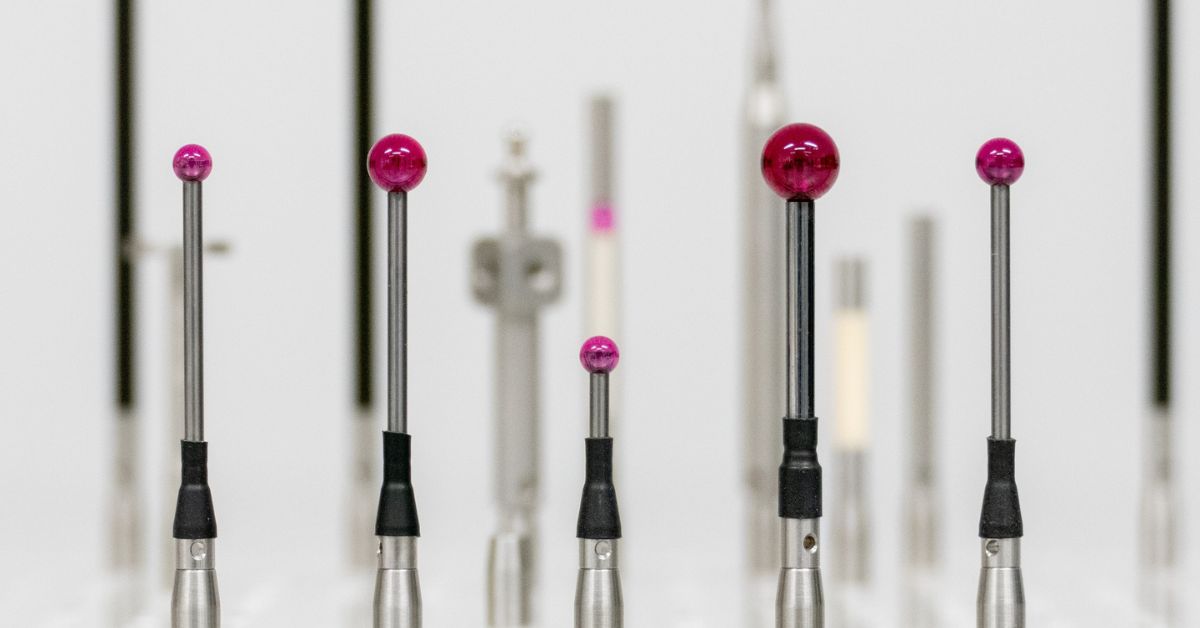

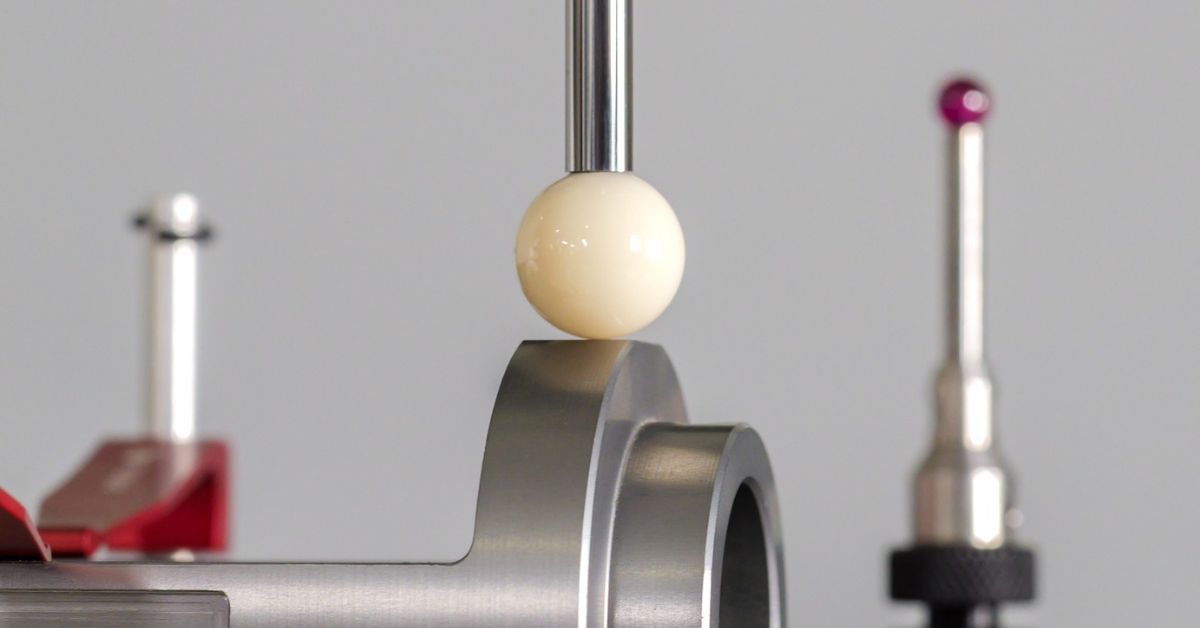

High-quality diamond styli for metrology applications play a role in driving accuracy. This precision proves particularly valuable in industries where component failures can have catastrophic consequences, such as aerospace engine components or medical implants.

Versatility in Measurement

Modern CMMs accommodate an impressive range of measurement tasks across diverse part geometries and sizes. These machines adapt to various measurement requirements, from small electronic components to large automotive panels, through interchangeable probe systems, flexible fixture options, and programmable measurement routines.

The versatility extends to material compatibility, as well. CMMs measure metal, plastic, ceramic, and composite materials without requiring different measurement approaches. This flexibility allows manufacturers to consolidate multiple inspection processes into a single, streamlined operation.

Boosted Efficiency

CMMs reduce inspection time compared to traditional measurement methods. Automated measurement routines can evaluate hundreds of features in minutes, while manual inspection of the same components might require hours or even days. This translates directly into increased throughput and reduced production bottlenecks.

The automation capabilities enable lights-out operation, allowing CMMs to continue measuring parts during off-shifts. This continuous operation maximizes equipment utilization and provides faster feedback to production teams for quicker corrective actions when dimensional issues arise.

Consistent and Repeatable Results

CMM automation eliminates the variations of manual measurements. The same measurement routine consistently produces identical results, regardless of the operator, time of day, or external factors that typically influence manual inspection. This consistency is invaluable for maintaining quality standards across multiple shifts and production runs.

Repeatability also supports statistical process control initiatives by providing reliable data for trend analysis and process optimization. Manufacturers can confidently track dimensional variations over time, identifying subtle process drifts before they result in rejected parts.

Reduced Labor Costs

While CMMs require initial operator training, they reduce the skilled labor requirements for quality inspection. A single operator can manage multiple measurement setups; plus, automated routines minimize the need for constant supervision. Then, managers can redeploy skilled technicians to other valuable activities.

The reduction in manual handling also decreases the risk of part damage during inspection, costs associated with scrapped components, and rework.

Data Integration and Analysis

CMMs generate comprehensive measurement data that integrates seamlessly with quality management systems and statistical analysis software. This digital data stream enables advanced analytics, trend monitoring, and predictive quality insights that manual measurement methods cannot provide.

The data integration capabilities support Industry 4.0 initiatives by connecting measurement results with production parameters. This can warrant the use of closed-loop quality control systems that automatically adjust manufacturing processes based on dimensional feedback.

Notable Drawbacks of CMMs

High Initial Investment

CMM acquisition is a significant capital expenditure that can strain budgets, particularly for small-scale manufacturers. Leaders must factor in installation expenses, operator training, software licensing, and facility modifications to accommodate the equipment.

However, business leaders can mitigate some of these costs through informed purchasing decisions. By sourcing reliable, cost-effective replacement styli and accessories, leaders can extend the value of their CMM investment without compromising performance. The total cost of ownership might be higher, but it could pay off in the long run with the added benefits of reduced labor costs and better efficiency.

Complexity in Operation

CMMs require operators to have specialized knowledge and extensive training. Programming measurement routines, selecting appropriate probe configurations, and interpreting results demands technical expertise that may not be readily available within the current workforce.

These challenges are far from insurmountable. Investing in ongoing operator training can simplify operations. In addition, high-quality accessories can reduce setup complexity, while leveraging expert support can streamline processes.

Ongoing Maintenance Requirements

CMMs demand regular maintenance to preserve their accuracy and reliability. Calibration procedures, probe replacement, and system updates require scheduled downtime that can impact production schedules. The specialized nature of this maintenance necessitates factory-trained technicians or service contracts with equipment suppliers.

Proactive strategies can minimize the impact of maintenance on productivity and costs. Scheduling preventative maintenance, training in-house technicians to handle basic maintenance and calibration tasks, and investing in well-made components can ensure the long-term reliability of CMM systems.

Environmental Sensitivity

CMMs operate optimally within strictly controlled environmental conditions. Temperature variations, vibrations, and airborne contaminants can affect measurement accuracy. Maintaining controlled conditions requires additional investments in facility infrastructure, including HVAC systems, vibration isolation, and air filtration equipment. Routine environmental monitoring can help to address variances and reduce the risk of accuracy lapses.

Potential for Over-Reliance

Organizations may develop excessive dependence on CMM measurements, potentially neglecting other quality control methods that provide valuable insights. Over-reliance can create bottlenecks when CMMs require maintenance or when measurement requirements exceed machine capacity.

Avoid this drawback by integrating complementary measurement methods alongside CMMs. Handheld gauges or non-contact systems can provide additional insights and maintain workflow flexibility.

Limitations With Large or Unmovable Parts

Physical constraints due to oversized components or assemblies that cannot be transported to the measurement station limit CMM applications. While portable CMM systems exist, they typically sacrifice more accuracy and automation capabilities than fixed installations.

Manufacturers can explore alternative solutions, such as laser tracking systems or photogrammetry, which are well-suited for large assemblies. Combining these approaches with strategic planning can lead to great results.

Understanding the pros and cons of coordinate measuring machines is essential for navigating their complexity and benefits. By partnering with Itpstyli, manufacturers gain access to well-made, high-quality CMM styli and accessories that elevate precision and reliability.