12/22/25

Straight Styli and the Prevention of Deflection Errors

Precision in measurement hinges on the smallest components doing their job flawlessly. Styli may look simple, but their design directly influences whether a probe delivers trustworthy data or introduces costly inaccuracies. Among the many options available, engineers often turn to straight styli and the prevention of deflection errors as the foundation for dependable measurement. Explore how deflection occurs, why straight styli are the preferred choice for minimizing it, and the best practices that keep CMMs and machine tools performing at their highest level.

What Are Deflection Errors?

Deflection is the bending or flexing of a CMM stylus stem that occurs when its tip makes contact with the part being measured. While contact force is necessary for the probe to register a measurement, certain factors can cause the stylus to bend, even microscopically. This bending introduces inaccuracies because the CMM records the position at the moment of contact rather than the true location on the part's surface. This discrepancy is known as a deflection error.

Common Causes of Deflection:

- Too much pressure can cause the stylus stem to bend.

- Longer, thinner stylus stems are more susceptible to flexing under pressure.

- Using a complex stylus when a simpler one would suffice can increase the risk of deflection.

Consequences of Inaccurate Measurements:

These seemingly small errors can lead to significant problems, including parts that are out of tolerance, costly rework, and wasted production time. For example, when measuring a precise gear tooth profile, even a few microns of deflection error can result in a final product that fails quality inspection, despite measurement data suggesting it is correct. Minimizing deflection is fundamental to ensuring accurate, reliable results.

Why Straight Styli Are the Preferred Choice

When the goal is to minimize deflection, the simplest solution is often the most effective. A straight stylus, designed with a single rigid stem, provides the most direct alignment between the probe and the contact point. This straightforward construction is inherently more resistant to bending and flexing compared to complex configurations like star or cluster styli, which have multiple joints that can introduce deflection.

Key Benefits of Using a Straight Stylus:

- Its simple, rigid design offers superior stiffness, minimizing deflection errors during measurement.

- By reducing the variable of deflection, straight styli deliver more reliable and precise data, especially in linear probing applications.

- The uncomplicated design makes the calibration process quicker and more straightforward, ensuring consistent performance.

Due to these advantages, straight styli are the preferred choice when precision is paramount. They excel in applications such as:

- High-precision gear measurement: Ensuring flank and root profiles meet exact specifications.

- Tight-tolerance aerospace or automotive components: Verifying critical dimensions where even micron-level errors are unacceptable.

- Routine CMM checks: Delivering the high degree of repeatability required for quality control processes.

For any simple, unobstructed measurement, a straight stylus should be the default choice. Using the shortest and most rigid straight stylus possible for an application is a foundational principle of good metrology practice, enhancing the quality and reliability of your measurement data.

Factors That Influence Stylus Performance

If you want your stylus to perform at its best while minimizing deflection, pay attention to these key factors:

Material of the Stem

The stem is the part of the stylus most responsible for rigidity. Carbide is excellent for short-to-medium styli, while carbon fiber balances stiffness and weight for longer reach. Ceramic offers thermal stability but less stiffness, and steel is more prone to bending. Choosing the right stem material ensures the stylus resists deflection under probing force.

Ball Tip Material

The ball tip makes direct contact with the surface, so its material matters. Ruby is versatile but can wear against hardened steel, while silicon nitride resists abrasion in tougher applications. Zirconia adds strength and chip resistance, making it reliable in demanding environments. Matching the tip to the surface helps maintain accuracy and extend stylus life.

Length and Diameter Trade-Offs

Stylus geometry directly affects stiffness. Longer styli reach deeper features but flex more easily, while shorter stems with larger diameters stay rigid. Doubling the diameter increases stiffness dramatically, making the stylus far more resistant to bending. The best practice is to use the shortest, thickest stylus that still fits the measurement.

Environmental and Task Considerations

Conditions around the measurement can influence stylus choice. Ceramic stems handle temperature changes well, while carbon fiber reduces mass when probing delicate parts. Tip materials should also match the surface. Factoring in these details ensures the stylus is suited to the job, not just the geometry.

Best Practices for Preventing Deflection Errors

Minimizing deflection errors starts with following practical, proven strategies in your measurement routine. Here are some key tips engineers rely on:

- Regularly check your stylus for wear, damage, or contamination to maintain consistent performance and reliability.

- Use extensions and adapters sparingly, as they can introduce instability and increase the risk of deflection.

- Regular calibration is essential. Ensure stylus calibration matches the probing force and speed used during actual inspection to catch deflection early and avoid discrepancies.

Additionally, maintain proper probing techniques. Always aim to measure with the stylus perpendicular to the surface to direct forces axially along the stem and reduce lateral loads. Keep probing speeds and forces as low as possible while still ensuring reliable triggering.

Custom Solutions and When to Consider Them

While standard styli work for most applications, certain complex geometries demand custom solutions. Deep or hard-to-reach features, tight spaces, or delicate parts requiring low contact force are examples where a standard stylus may fall short.

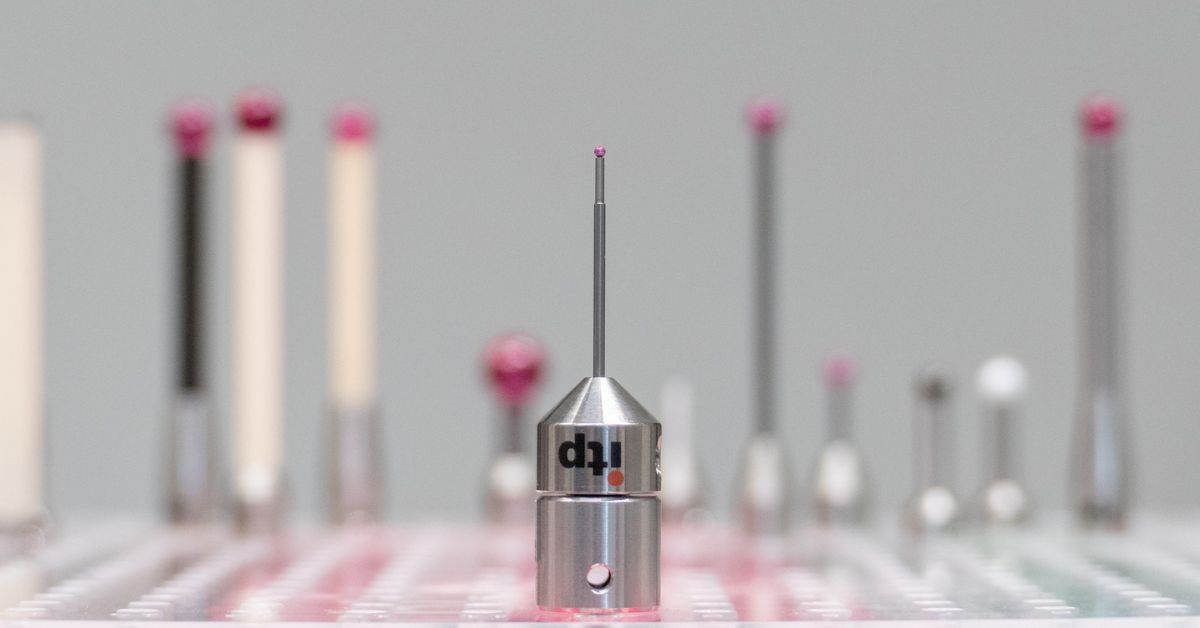

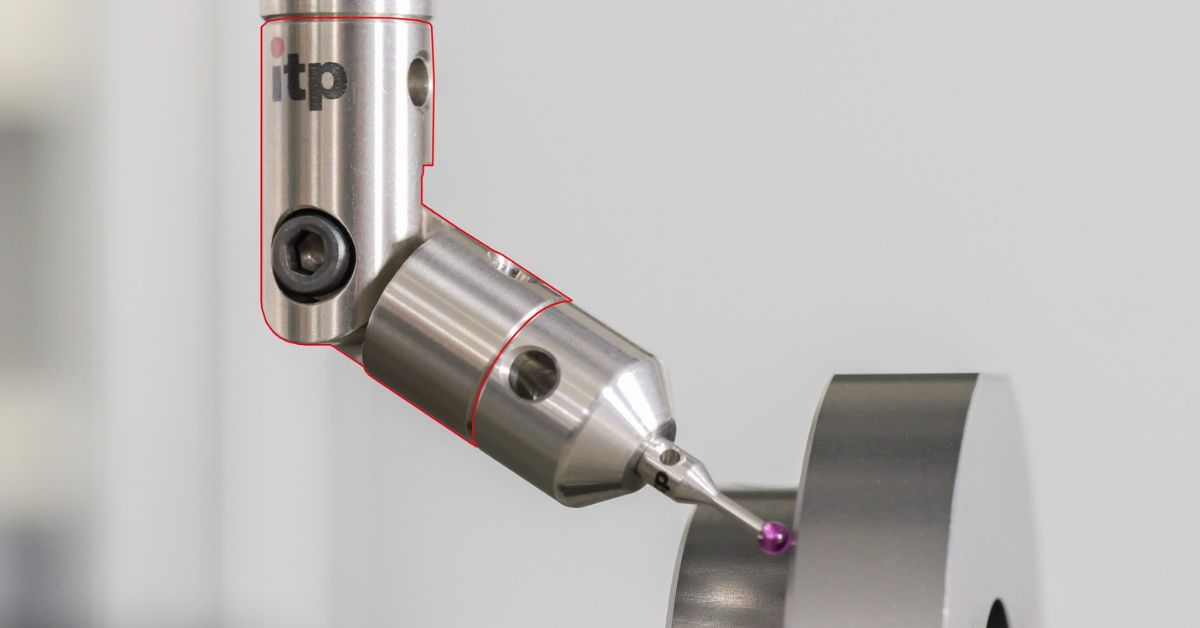

This is where itpstyli can help. As experts in metrology, we design bespoke styli tailored to your specific needs to ensure the perfect balance of reach, clearance, and rigidity. From custom lengths and diameters to unique material combinations like carbon fiber stems or specially shaped tips, our solutions are crafted for precision and durability.

In addition to custom styli, itpstyli offers a wide range of accessories to enhance performance, making them the ideal partner for tackling even the most intricate measurement challenges. Reach out today to explore how we can optimize your measurement tasks!

Achieving precision in manufacturing relies on controlling every variable, and deflection is a critical one. By understanding its causes and taking proactive steps to mitigate it, you can elevate the quality and reliability of your products. The proper application of straight styli and the prevention of deflection errors are cornerstones of this effort, providing the foundation for accurate, trustworthy measurement data.