Mounting / Gluing

Precision measurement hinges on the integrity of the bond between a sphere and its stem. Many stylus manufacturers overlook how ongoing vibration and stress can weaken this connection over time, resulting in early wear or inaccurate readings. itpstyli's peg mounting and curing process counteracts these issues by delivering unmatched stability and reliability.

An innovative approach ensures that our styli remain dependable, even under challenging manufacturing conditions. We extend this commitment to quality to every product in our portfolio, including specialized CMM probe extensions to meet unique operational needs.

As your trusted stylus manufacturers, we don’t outsource components like other businesses. Every step of our process is managed in-house for greater control and consistency. That means each part, from probes to extensions, provides the strength and longevity required for your quality control. Trust us to deliver solutions engineered for precision and lasting performance.

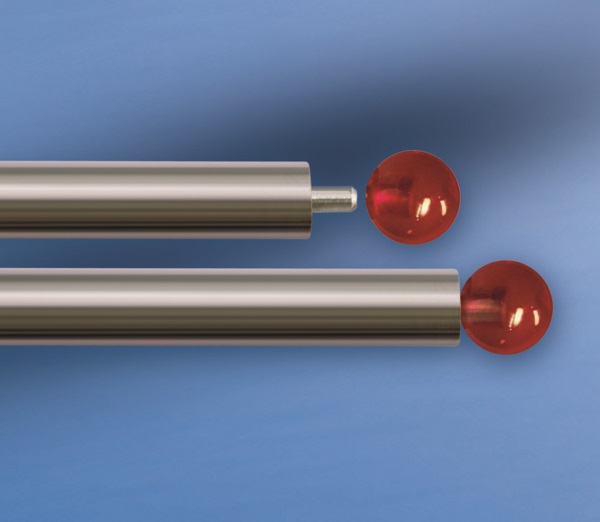

Sphere mounting: The peg mounting of spheres by means of special gluing methods ensures a maximum of stability and durability.

Curing: Our proprietary glue curing technology has been tested and optimized to deliver superior results. With commonly used mounting methods only a small amount of pressure is required to detach the sphere from the stem; especially with probes of small sphere diameters and thin stems.

The itp solution: twice as solid! Our probe spheres are peg mounted; from an engineering perspective to offer the best stability and maximizes the gluing surface. In order to achieve a long-term fixation, we use special gluing methods in combination with our own specially developed and tested glue curing technology, which is used in our climate-controlled labs. The result: great stability and durability.