Precision and Quality Specified

| Ruby spheres | Ceramic spheres | Silicon nitride spheres | Zirconia oxide spheres | |

|---|---|---|---|---|

| Material |

Synthetic ruby |

Aluminum oxide |

Silicon nitride |

Zirconia oxide |

| Form deviation¹ |

0,08µm - 0,13µm |

0,08µm - 0,13µm |

0,08µm - 0,13µm |

0,08µm - 0,13µm |

| Diameter deviation |

0,08µm - 0,13µm |

0,08µm - 0,13µm |

0,08µm - 0,13µm |

0,08µm - 0,13µm |

| Roughness Ra |

0,007µm - 0,008µm |

0,007µm - 0,008µm |

0,004µm - 0,005µm |

0,007µm - 0,008µm |

| Hardness |

2400 Vickers |

2100 Vickers |

1600 Vickers |

1200 Vickers |

| Density |

3,99 g/cm3 |

3,85 g/cm3 |

3,20 g/cm3 |

6,05 g/cm3 |

| Thermal expansion |

5,4•10-6K-1 |

8,8•10-6K-1 |

2,9•10-6K-1 |

10,5•10-6K-1 |

| Compression strength (MPa) |

2100 |

3800 |

3000 |

2000 |

| Bending strength (MPa) |

400 |

470 |

>1000 |

700 - 1100 |

| Fracture toughness (MN/m3/2) |

1 |

4 |

>6,5 |

10 |

¹ From AFBNA Grade 3 to Grade 5

| Material | Hardness | Density | |

|---|---|---|---|

| Titanium |

3,7035 Grade 2 |

150 Brinell |

4,5 g/cm3 |

| Stainless Steel |

1,4305 |

300 Vickers |

7,95 g/cm3 |

| Tungsten Carbide |

DK 120 |

1700 Vickers |

15,0 g/cm3 |

| Ceramic |

Alsint 99,7 |

9 nach Mohs |

3,85 g/cm3 |

| Carbon Fiber |

Bending strength > 450 GPa CTE (Coefficient of thermal expansion) -0,4 x 10-61/K |

||

- Carbide / Carbide tube

- Ceramic

- Stainless Steel

- Carbon Fiber

- Titanium tube

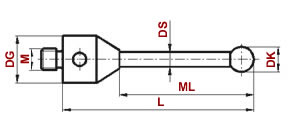

- M2 = 3 mm

- M3 = 4 mm

- M4 = 7 mm

- M5 = 10 mm compatible Renishaw

- M5 = 11 mm compatible Zeiss

- M5 = 12 mm compatible Leitz

- M6 = 16 mm