Tooling configurations used on fixed-head probe systems provide great flexibility in the type of products that can be measured due to their allowance of using longer and heavier probe configurations. However, these configurations often require more complex assemblies which are "built-up" using many standard components screwed together to achieve the alignments needed to measure necessary features. Some of the challenges with these assemblies include the following:

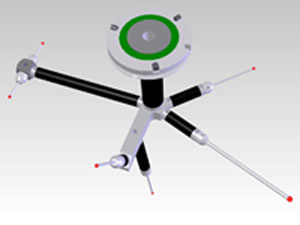

Custom probe tooling consists of a rigid assembly, fabricated at the proper lengths and angles to measure all the needed features properly. These assemblies are constructed using high quality, temperature stable materials. Properly executed, this approach will provide:

By designing (or modeling existing) part holding fixtures and custom probe tooling in a virtual 3D space, one can readily test the design for functionality and possible interferences. Proper CAD can prove that all the angles, lengths, and styli are correct for the given application, thus eliminating the need for expensive reworking of the custom manufactured parts.

In most measurement environments temperature is the largest source of measurement variation, making the use of temperature stable materials critical.

Titanium is the material of choice for customized probe holders because of its low weight and thermal properties.

Temp-Comp™ thermally stable extensions are another critical component due to their high quality and exceptionally low cost. The unique double-wound carbon fiber and titanium construction provide a near-zero coefficient of expansion along with exceptional torsional rigidity that is not possible with typical carbon fiber.

There is only so much room for variation from spec before a customized holder becomes unusable. Minor angular errors of a probe can cause probe shanking, leading to invalid measurements.

Customers have come to rely on itpstyli, LLC to provide machined titanium holders because of our consistency in meeting tight tolerances and ability to accurately cut compound angles.

Please call to learn more about how itpstyli and its partners can provide turn key solutions for designing and manufacturing fixed-head tooling systems.

Customized and affordable tooling systems provide maximum rigidity, enhanced thermal stability and require minimal maintenance and maximum repeatability.