10/15/25

Why Metrology Is Important for Manufacturing

In any high-precision manufacturing setting, the difference between a perfect component and a piece of scrap can be measured in microns. Accuracy is not just a goal; it is the foundation of quality, safety, and profitability. This is where metrology, the science of measurement, becomes an indispensable part of the production process.

Understanding why metrology is important for manufacturing is the first step toward optimizing quality control and achieving operational excellence. It moves measurement from a simple final check to an integrated, value-adding activity that influences the entire production lifecycle.

What Is Metrology on the Shop Floor?

Metrology is the science of measurement. On the manufacturing floor, this scientific discipline becomes a practical tool for verifying that parts conform to design specifications. It involves using specialized equipment to quantify the physical dimensions and geometric characteristics of a manufactured object. This includes everything from simple hand tools like calipers to highly advanced Coordinate Measuring Machines (CMMs).

The role of metrology extends far beyond a simple pass/fail judgment. It provides critical data that informs process adjustments, identifies tool wear, and validates the consistency of production. A robust metrology program enables a company to transition from reactive quality control to proactive quality assurance. When defects were once identified after the fact, there are now processes that monitor and control quality to prevent defects from occurring in the first place.

This shift empowers manufacturers to produce better parts more consistently.

Linking Metrology to Quality and Compliance

Quality and metrology are fundamentally intertwined. Without accurate measurement, there is no objective way to confirm that a product meets its required standards. This connection is especially critical in industries where component failure has serious consequences, such as aerospace, medical device manufacturing, and automotive.

Quality Control and Assurance

Metrology provides the data manufacturers need for a strong quality management system (QMS). By measuring parts at various stages of production, operators can detect deviations from the nominal design before they escalate into larger problems.

This in-process inspection strategy helps maintain process stability and improves the overall quality of the final output. The data collected serves as proof that the manufacturing processes are under control and capable of producing parts within the specified tolerances.

Regulatory Compliance and Traceability

For many industries, metrology is a non-negotiable requirement for regulatory compliance. Medical and aerospace components, for example, must have a documented history that proves every dimension meets stringent safety and performance standards.

Metrology creates an auditable trail of data for each part. This traceability is essential for recalls, process validation, and certification with regulatory bodies such as the FDA or FAA. Accurate measurement records demonstrate due diligence and protect a company from liability.

Boosting Efficiency and Reducing Costs

A well-implemented metrology strategy offers significant financial benefits by improving efficiency and lowering the overall cost of quality. When measurement is integrated directly into the manufacturing workflow, it helps identify and correct issues more quickly, thereby minimizing waste and rework.

Improving Throughput and Reducing Scrap

Advanced measurement systems, like CMMs, can inspect parts much faster than traditional manual methods. This speed allows for higher sampling rates or even 100% inspection without creating a bottleneck in production.

By catching dimensional errors early, manufacturers can adjust machine offsets or replace worn tooling immediately. This proactive approach drastically reduces the number of non-conforming parts produced, which in turn cuts down on scrap and the associated material and labor costs.

Lowering the Cost of Quality

The cost of quality is a metric that includes all costs associated with preventing, detecting, and remediating defects. Ineffective metrology increases these costs. Bad parts that pass inspection may cause failures in the field, resulting in warranty claims, recalls, and damage to a brand's reputation.

Conversely, good parts that are incorrectly rejected due to a poor measurement process result in unnecessary scrap. Precise metrology reduces both of these errors, optimizing resource use and protecting profitability.

Metrology in Advanced Manufacturing

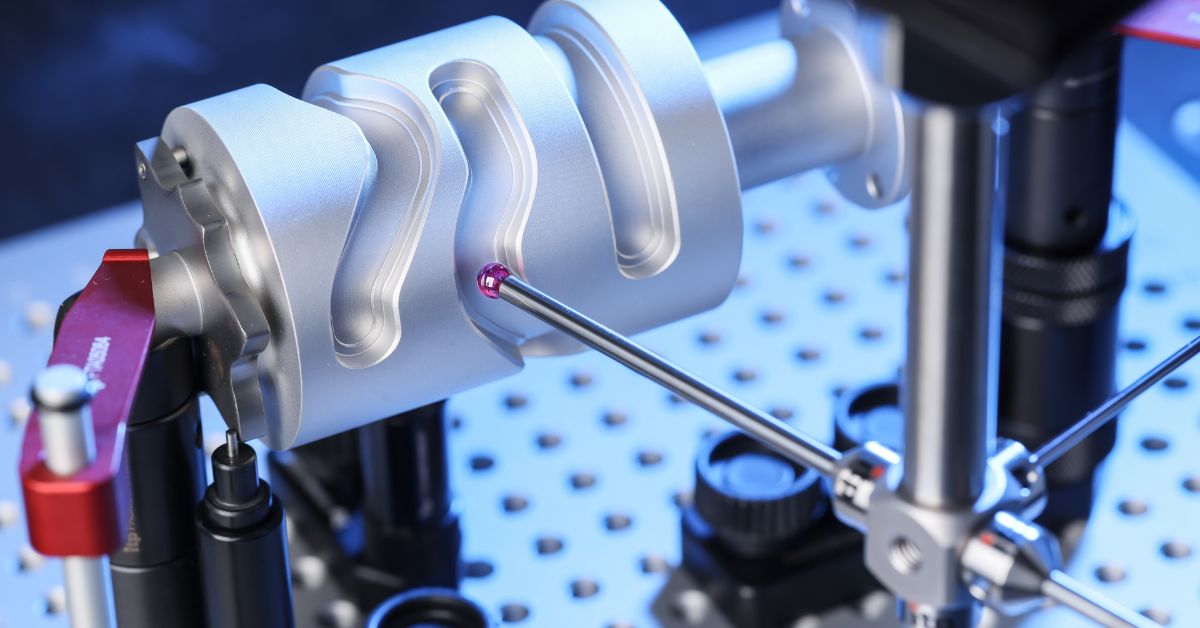

Modern manufacturing relies on sophisticated technologies, and metrology has evolved in tandem with them. CMMs, their probes, and styli are pillars of today's smart factory, providing the high-fidelity data engineers need to control complex processes.

These systems use tactile probes to gather precise coordinate data from a part's surface. The integrity of that data begins with the point of contact: the probe and its stylus. A high-quality measuring stylus with the correct tip material, stem rigidity, and design for the application is essential for collecting accurate and repeatable measurements.

The data gathered informs everything from initial part qualification to the automated feedback loops that drive lights-out manufacturing.

Practical Considerations for Measurement Success

Achieving reliable measurement data depends on more than just the machine itself. The accessories, setup, and maintenance practices are just as important.

Selecting the Right Tools for the Job

Choosing the right probes, styli, and fixtures is critical. A stylus with a fragile stem may break during an automated routine, while a fixture that allows a part to move during measurement will produce useless data.

The material of the stylus tip—such as ruby, silicon nitride, or diamond—should be selected based on the material of the part being measured to avoid wear and measurement inaccuracies. Partnering with a knowledgeable supplier, like itpstyli, offers a diverse range of high-quality styli and accessories, simplifying this process.

Avoiding Common Measurement Pitfalls

Many measurement errors stem from correctable issues. Poorly maintained equipment, uncalibrated probes, and improper part cleaning can all compromise data quality.

Regular maintenance and calibration are fundamental to trustworthy metrology. Using accessories that are worn or not suited for the task is another common error. A high-quality CMM is only as good as the stylus at the end of its probe. Investing in durable, high-performance accessories is a small price to pay for data integrity.

The Importance of Data Integrity and Calibration

The data produced by metrology systems is used to make important business decisions. Therefore, the integrity of that data is paramount.

Calibration is the process of comparing a measurement device against a known standard to verify its accuracy. Regular calibration of CMMs, probes, and styli is essential for maintaining confidence in measurement results. This practice ensures that the data accurately reflects the true state of the part, rather than errors in the measurement system.

Metrology is a cornerstone of modern manufacturing, providing the objective data needed to control processes, verify quality, and achieve operational efficiency.

A commitment to precise measurement, supported by high-quality equipment and accessories, is a direct investment in a company's success. Ultimately, a deep understanding of why metrology is important for manufacturing empowers businesses to build better products, cultivate customer trust, and secure a competitive edge in a demanding market.