8/7/25

What Is the Importance of Calibration in Metrology?

Imagine crafting a high-precision component for an aerospace application, only to discover that its measurements are slightly off. The consequences could range from costly delays to catastrophic failures. Such scenarios underscore the importance of calibration in metrology. Calibration ensures that measuring instruments provide accurate and reliable results, serving as the foundation for quality assurance across various industries.

Take a closer look at why calibration is not just a technical requirement but a critical practice for precision, safety, and compliance. Whether you're in manufacturing, healthcare, or any field that relies on exact measurements, understanding the role of calibration could save you time, money, and reputation. Continue reading to learn how calibration safeguards your operations and enhances your outcomes.

The Science Behind Calibration

Calibration relies on the principle of comparison against established standards. By measuring a known reference standard with an instrument, deviations from the expected value can be identified. These deviations form the foundation for either adjusting the instrument or applying correction factors to future readings to ensure precision.

A key aspect of calibration is measurement traceability. Every calibration must connect to national or international standards through a documented, unbroken chain of comparisons that ultimately links back to fundamental physical constants. This ensures reliability and consistency, allowing measurements made under different conditions to be directly compared and trusted.

Measurement uncertainty is another critical factor. Variables such as instrument drift, environmental conditions, operator techniques, and standard limitations can introduce doubt into measurements. Effective calibration doesn’t eradicate uncertainty, but it controls and quantifies it within defined limits, ensuring that results remain accurate and reliable.

Why Calibration Is Crucial in Modern Industries

Modern manufacturing and research environments demand unprecedented levels of precision. Industries such as aerospace, automotive, electronics, and pharmaceuticals rely on accurate measurements to ensure product safety, regulatory compliance, and competitive advantage.

Aerospace and Defense Applications

The aerospace industry exemplifies the critical nature of calibration. Aircraft components must meet extremely tight tolerances to ensure safety and performance. A single measurement error in critical dimensions can lead to part rejection, costly rework, or safety incidents. Calibration ensures that coordinate measuring machines (CMMs) and other precision instruments maintain the accuracy required for these demanding applications.

Pharmaceutical and Medical Device Manufacturing

In pharmaceutical manufacturing, calibration has a direct impact on patient safety. Analytical instruments used for drug potency testing, contamination detection, and quality control must provide reliable results. Regulatory bodies such as the FDA require comprehensive calibration documentation as part of good manufacturing practices.

Electronics and Semiconductor Production

The electronics industry operates at microscopic scales where even minor measurement errors can render products unusable. Calibration of measurement equipment ensures that semiconductor devices meet their specified electrical and physical parameters, directly impacting product yield and reliability.

Benefits of Regular Calibration

Regular calibration offers numerous benefits that go far beyond achieving measurement accuracy. Here’s how it enhances operations across various dimensions:

Operational Efficiency

- Identifies instrument issues before they disrupt production, minimizing downtime and errors

- Ensures measurements support more precise manufacturing, reducing waste and enabling tighter safety margins

- Prevents the production of out-of-spec products, cutting back on costly rework and scrap

Cost Savings and Risk Mitigation

- Accurate equipment reduces the chances of defective products reaching customers.

- Proper calibration practices can lower liability risks, often leading to reduced insurance premiums.

- Routine calibration helps identify maintenance requirements, thereby extending the lifespan of machinery.

- Reliable instruments enable better process monitoring and tighter operational control.

Regulatory Compliance and Audit Preparation

- Many sectors demand strict compliance with calibration guidelines.

- A well-maintained calibration program simplifies documentation for regulatory inspections and certifications.

- Proper calibration demonstrates reliability, building trust with regulators, customers, and stakeholders.

By implementing regular calibration, organizations can improve product quality, safeguard their reputation, and protect their bottom line.

Consequences of Neglecting Calibration

Neglecting calibration can lead to cascading problems that significantly outweigh the investment in proper maintenance. Over time, uncalibrated instruments drift from their intended accuracy, resulting in systematic measurement errors that may go unnoticed until they impact entire production runs. The fallout often includes product recalls, customer dissatisfaction, and regulatory violations, all of which can erode an organization’s reputation and financial stability.

Legal and financial risks further compound the issue. Products made with uncalibrated equipment may fail to meet specifications or cause harm, exposing companies to lawsuits and potential liability. Additionally, organizations may face denied insurance claims if improper maintenance of measurement tools is identified as a contributing factor in an incident.

The Role of Standards and Accreditation in Calibration

Calibration standards provide reference points that ensure measurement consistency across different organizations and locations. International standards such as ISO/IEC 17025 establish requirements for calibration laboratory competence, while industry-specific standards address unique measurement challenges.

ISO/IEC 17025 and Laboratory Accreditation

ISO/IEC 17025 specifies the general requirements for the competence of testing and calibration laboratories. Accreditation to this standard demonstrates that a calibration laboratory has the technical competence to perform specific calibrations. This accreditation provides confidence in calibration results and facilitates international trade by ensuring measurement compatibility.

National and International Measurement Standards

National metrology institutes maintain primary standards that serve as the foundation for all calibration activities. These institutes work together to ensure global measurement consistency through international comparisons and collaborative research. This cooperation enables manufacturers to sell products worldwide with confidence in their measurement systems.

The Calibration Process: Step-by-Step

Effective calibration follows a systematic approach that ensures thorough evaluation and documentation. The process begins with pre-calibration preparation and continues through final certification.

Pre-Calibration Assessment

Before beginning calibration, technicians must assess the instrument's condition and operating environment. This assessment includes:

- Visual inspection for damage or wear

- Verification of environmental conditions

- Review of previous calibration history

- Selection of appropriate standards and procedures

Calibration Execution

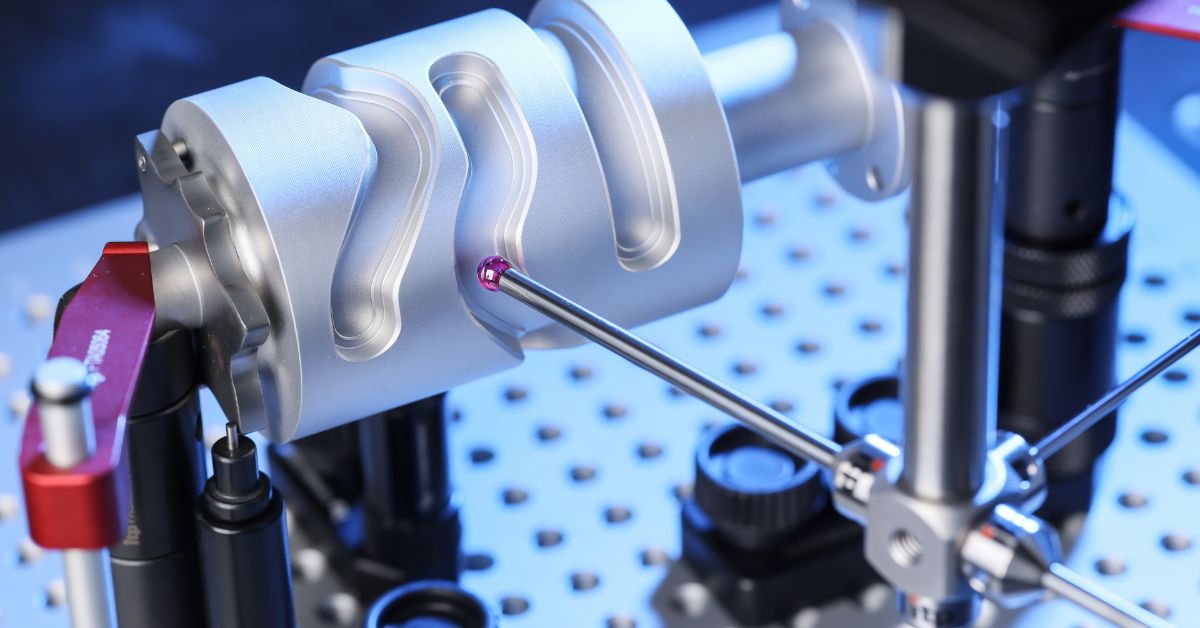

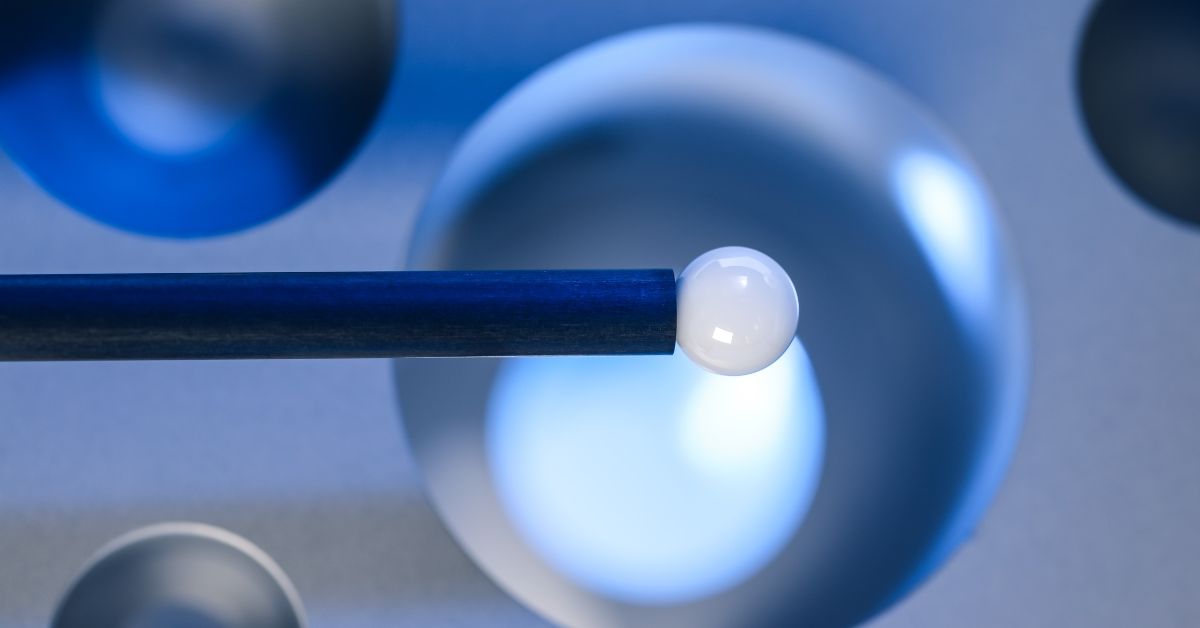

The actual calibration process involves a systematic comparison of the instrument under testing with reference standards. For coordinate measuring machines, this might include verification using a CMM calibration sphere to check probe accuracy and machine geometry. The calibration technician records all measurements and environmental conditions during the process.

Data Analysis and Certification

After completing measurements, technicians analyze the data to determine if the instrument meets its specifications. This analysis includes calculating measurement uncertainty and determining whether adjustments are necessary. The final step involves issuing a calibration certificate that documents the instrument's performance and traceability.

Precision and trust are the cornerstones of progress in any industry, and they hinge on the importance of calibration in metrology. Consistent, reliable calibration is more than a technical process—it’s a commitment to excellence.

By prioritizing calibration, you establish a standard for quality that safeguards your operations while also enhancing your impact in a competitive world. Now is the time to ensure your measurements reflect the precision your goals deserve.