9/17/25

What Are the Main Causes of CMM Measuring Errors?

Measurement accuracy in high-stakes industries such as medical, aerospace, and electronics can’t be left to chance. A coordinate measuring machine (CMM) is one of the most trusted tools for verifying the dimensional accuracy of components. It ensures that every part meets strict specifications before reaching customers or entering critical assemblies.

However, even with cutting-edge technology, measurement errors are not uncommon. These errors can quickly lead to scrap, rework, or production delays. To help you avoid these pitfalls, Itpstyli has a guide to the main causes of CMM measuring errors, why they matter to your business, and the practical steps you can take to prevent them.

Why CMM Accuracy Matters

CMM accuracy plays a critical role in driving compliance, ensuring safety, and delivering high-quality products. For manufacturers in industries such as aerospace or medical devices, even minor errors in measurement can lead to serious consequences. These include regulatory issues, safety risks, and costly fixes.

Have you found yourself facing frequent inconsistencies or unexpected downtime? Understanding what causes CMM errors is the first step to fixing them. When you address these issues early, you protect your reputation for reliability and maintain operational efficiency.

The Main Causes of CMM Measuring Errors

Despite their precision, CMMs are sensitive systems susceptible to several error sources. Here are the primary factors influencing measurement inaccuracies and steps you can take to reduce their impact.

Environmental Factors

CMMs don’t operate in isolation. Their surroundings have a direct impact on performance. Common environmental challenges include these:

- Temperature shifts: Small fluctuations in temperature can cause thermal expansion or contraction in both the machine and the parts. For example, a minor change in size could affect how aerospace parts fit during assembly.

- Vibration: Nearby equipment, foot traffic, or even building movement can cause vibrations that disrupt high-tolerance measurements.

- Humidity: Excessive moisture can degrade materials or contaminate parts. This leads to inconsistent readings.

Prevent This Issue

Keep your environment stable by regulating temperature and humidity. Add dampening systems to reduce the impact of nearby vibrations. Incorporate thermal compensation software, which adjusts measurements in real time for environmental factors.

Machine-Related Issues

Errors can and will stem from problems within the CMM itself. Here is what you might find if it’s a machine-related error:

- Wear and misalignment: Over time, mechanical components such as bearings and guideways degrade. This wear impacts precision and can compound inaccuracies.

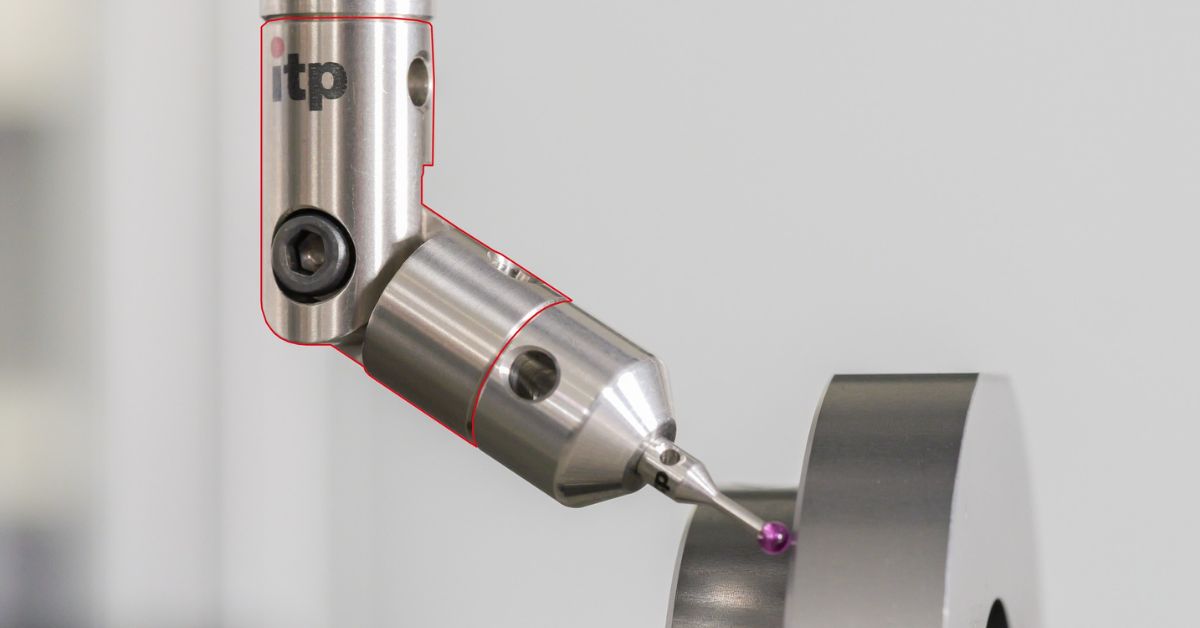

- Calibration gaps: Without routine calibration, small misalignments in the machine accumulate and affect measurements.

Prevent This Issue

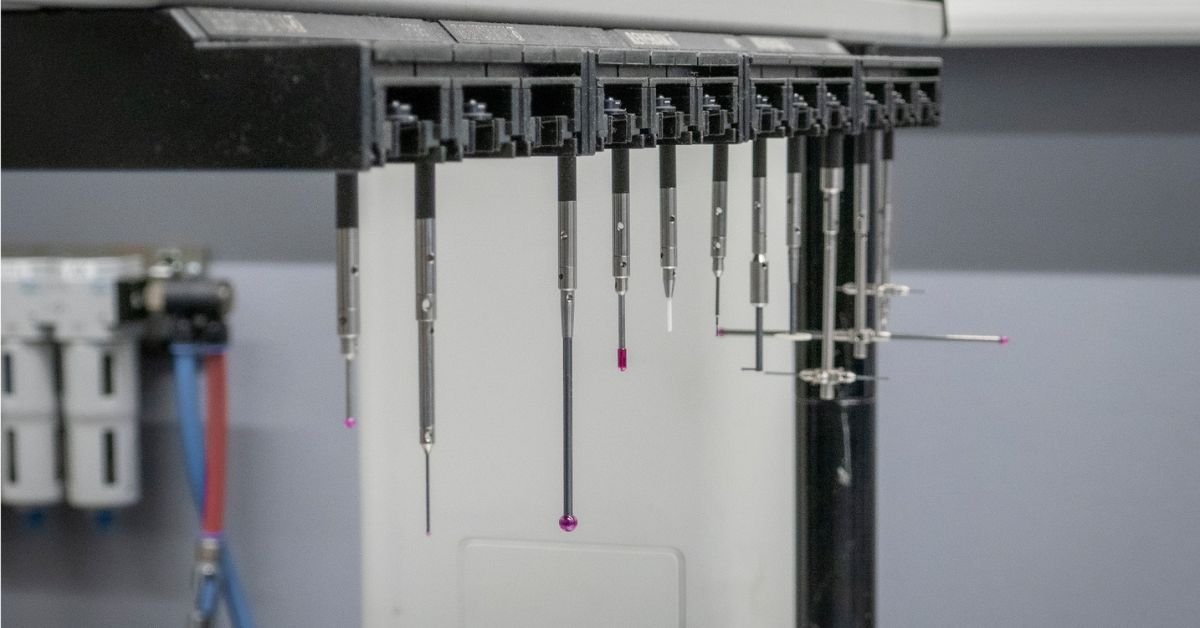

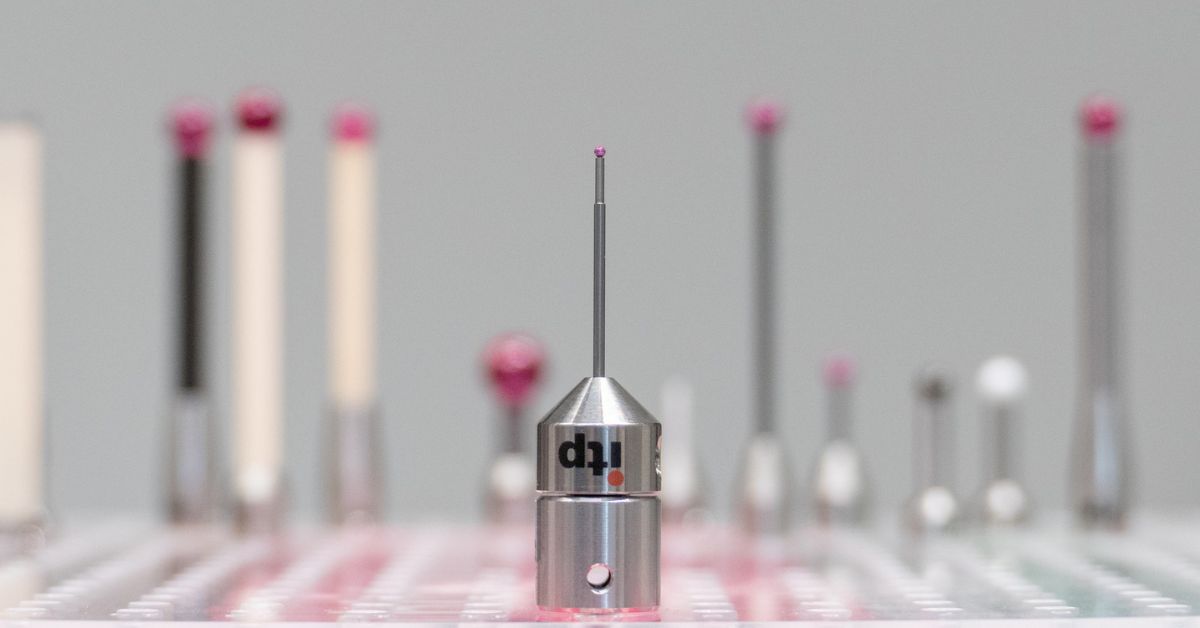

Proactive maintenance is essential. Schedule regular service checks, and use trusted calibration tools to maintain accuracy. A CMM calibration ball, specifically, ensures your machine remains aligned and performs reliably.

Operator Errors

Even the best machines rely on skilled operators. But human error is one of the most common causes of inconsistencies. Mistakes often include the following:

- Fixturing mistakes: Incorrect part placement or clamping can distort components and make it difficult to get consistent results.

- Probing technique: Misaligned probing angles or incorrect points introduce further inaccuracies.

Prevent This Issue

Provide thorough training for your team to standardize best practices. Use structured checklists to guide operators step-by-step and reduce variability. When everyone follows a consistent process, errors naturally decrease. Adopting a culture of ongoing learning can go a long way toward smoother production and fewer mistakes.

Workpiece Factors

So, the machine or the operator could be the issue, but what about the actual part? The characteristics of the piece you’re manufacturing and measuring can also create challenges:

- Material instability: Lightweight or delicate parts can deform under clamping. For instance, over-clamping a thin medical implant can distort results.

- Surface contamination: Dust, oil, or residue can interfere with probing accuracy.

- Size and complexity: Measuring a small electronics part requires different considerations than a large aerospace component.

Prevent This Issue

Clean each of your workpieces thoroughly before measurement. Avoid distortion by adjusting your clamping pressure for sensitive components and handling each part with care. For more complex parts, custom-fixturing solutions can provide additional support and stability.

Software & Programming Errors

CMM software is a powerful tool. However, programming flaws or outdated software can compound hardware-related issues. Here are some common pitfalls:

- Misaligned tolerances: If software tolerances don’t match your specifications, it leads to misleading results.

- Data input errors: Skipping verification runs, loading incorrect programs, or using outdated software versions amplifies errors across batches.

Prevent This Issue

Update your software regularly to ensure it’s compatible with your equipment and modern specifications. Always verify data inputs before starting a measurement cycle. Regularly run practice measurements to validate program accuracy and identify discrepancies.

Your Action Plan for Reliable CMM Accuracy

Understanding the causes of CMM measuring errors is only the first step. The real value lies in applying that knowledge through habits and systems that ensure accuracy every day. Here’s an action plan to help your team build a culture of precision.

Document and Standardize Procedures

Create clear standard operating procedures (SOPs) for measurement tasks. Standardization reduces variability between operators and ensures consistency across shifts or facilities.

Schedule Regular Performance Audits

Don’t wait until errors appear in production. Periodically review measurement data, compare against reference artifacts, and confirm that accuracy trends are holding steady.

Track and Analyze Error Data

Keep a log of measurement discrepancies, rework instances, or failed inspections. Over time, patterns will emerge that reveal systemic issues. This helps you fix root causes rather than symptoms.

Integrate CMM Data With Quality Management Systems

Connecting your CMM output to broader quality control systems gives you a single source of truth for compliance, traceability, and continuous improvement.

Partner With Trusted Experts

Work with calibration tool providers, service technicians, and training partners who specialize in your industry. The right partnerships ensure that your CMM program evolves in tandem with your manufacturing needs. With this proactive approach, your CMM will become a cornerstone of your quality strategy.

The main causes of CMM measuring errors stem from a host of different factors. The good news is that these challenges are entirely preventable with the right strategies and tools. Staying ahead of these errors helps you protect your product’s quality and avoid costly production setbacks.

Partner with Itpstyli for reliable calibration tools and expert support. Our solutions help you maintain peak CMM performance and achieve consistent, precise results every time. Elevate your measurement processes with tools you can depend on.