11/15/25

Ways To Improve Quality Control in Manufacturing

Every process in manufacturing—whether it's shaping a precision gear for aerospace or assembling a delicate circuit board for the medical field—depends on controlling countless details. Even minor inconsistencies can impact performance or safety, putting a company's reputation at risk.

Meeting strict industry requirements involves the use of well-designed systems and everyday diligence on the shop floor. Using practical ways to improve quality control in manufacturing can drive tangible results and success. From refining measurement strategies to optimizing equipment and training personnel, these steps help build a comprehensive quality management system.

Define a Clear Measurement Strategy

A sound measurement strategy is the starting point for effective quality control. It dictates what you measure, how you measure it, and why.

A poorly defined plan results in inconsistent data and unreliable inspections. Your strategy should identify critical-to-quality (CTQ) features for every part. These are the dimensions and characteristics that directly impact the product's function, fit, and performance.

Once you identify the CTQs, establish precise tolerance bands for each feature. The strategy must also specify the measurement method and equipment for each dimension. A complex internal bore in an aerospace component may require a coordinate measuring machine (CMM). In contrast, the outer diameter of a medical screw can be measured using a digital caliper.

Documenting these requirements in a formal control plan creates a repeatable and standardized process for all operators and inspectors.

Select the Right CMM Probes and Styli

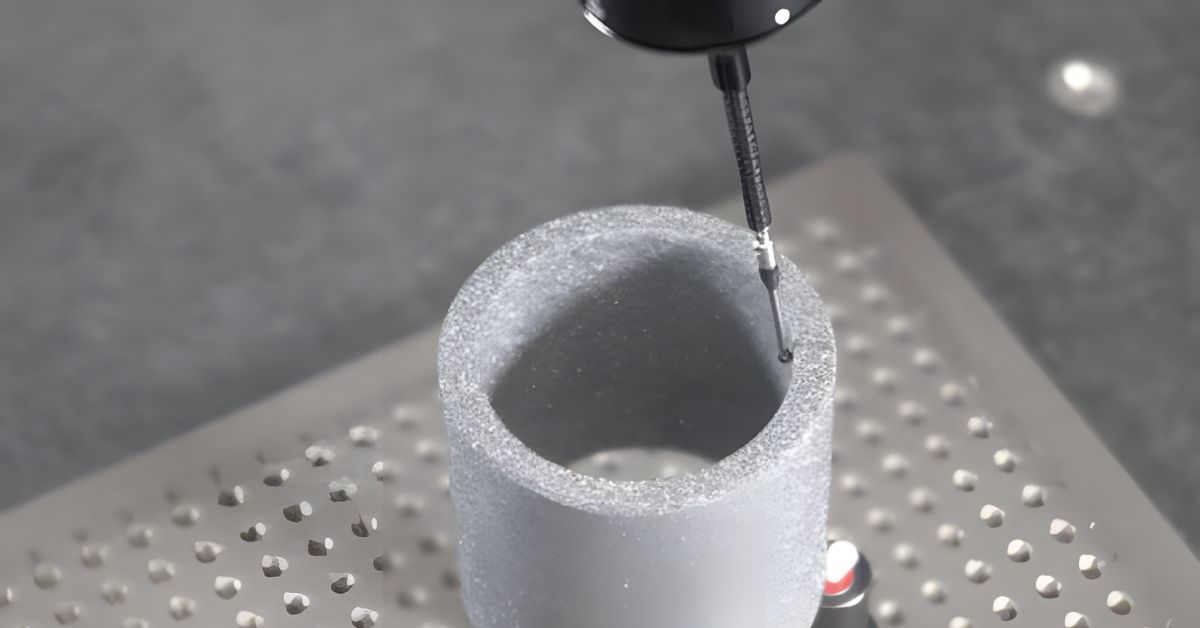

Coordinate measuring machines are central to modern metrology, but their accuracy depends entirely on the probing system. The probe and stylus are the only parts of the CMM that physically touch the workpiece. An incorrect choice here will invalidate your measurement data, no matter how advanced the machine is.

The type of stylus you select should match the feature you are inspecting. A simple spherical ruby tip is versatile for many applications, but measuring soft aluminum might require a different material to avoid abrasive wear. Inspecting a small, deep feature on an electronic connector might necessitate a slender, star-shaped configuration.

For unique geometries or highly specialized components, sourcing custom CMM styli becomes essential to access critical features without compromising accuracy. The material, tip size, stem length, and configuration of the stylus all influence the final measurement result.

Conduct Gauge R&R and MSA Studies

Having the right tools is only half the battle. You must verify that your measurement systems are reliable. Measurement system analysis (MSA), including gauge repeatability and reproducibility (gauge R&R) studies, evaluates the amount of variation within your measurement process.

- Repeatability assesses the variation when one operator measures the same part multiple times with the same gauge.

- Reproducibility assesses the variation when different operators measure the same part multiple times with the same gauge.

The goal of a gauge R&R study is to confirm that the variation from the measurement system is low compared to the part's tolerance. A high degree of variation indicates that your gauge, your operators, or your method is introducing error. Addressing these issues is fundamental to trusting your inspection data.

Adhere to Strict Calibration Schedules

Every piece of measurement equipment, from micrometers to CMMs, tends to drift over time. Regular calibration against a known, traceable standard is the only way to counteract this drift. A formal calibration program outlines the frequency and procedure for every gauge in your facility.

You should base the schedule on manufacturer recommendations, industry standards, and usage frequency. A gauge used hundreds of times a day on the shop floor will require more frequent calibration than one used weekly in a controlled lab.

Maintain detailed calibration records for each instrument. These records are crucial for audits, particularly in regulated industries such as medical device manufacturing, and for resolving quality issues.

Control the Manufacturing Environment

The environment where parts are made and measured directly affects their dimensions. Temperature and humidity fluctuations cause materials to expand and contract. This thermal expansion can introduce significant errors, especially when working with tight tolerances common in aerospace engine components.

Your quality lab and critical manufacturing areas should have strict environmental controls. The industry standard temperature for metrology is 20°C (68°F). Parts should be allowed to "soak" at this temperature before measurement to stabilize dimensionally. Controlling humidity also prevents rust and corrosion on both parts and precision equipment.

Implement Effective Fixturing

How a part is held during measurement is just as important as the measurement itself. Poor fixturing can distort the part and result in inaccurate readings. A good fixture holds the workpiece securely without deforming it and provides clear, unobstructed access to all features being measured.

Modular fixturing systems offer flexibility and repeatability. For high-volume production, dedicated fixtures designed for a specific part can accelerate the inspection process and reduce operator error. The fixture should be clean, stable, and designed to position the part in the same orientation every time.

Utilize Statistical Process Control (SPC)

While traditional QC inspects parts after they are made, statistical process control (SPC) monitors the manufacturing process in real-time. By collecting data and plotting it on control charts, operators can identify trends and variations before they result in out-of-spec parts.

SPC helps you move from a reactive "detect and sort" model to a proactive "predict and prevent" approach. When a process starts to drift toward a control limit, operators can make adjustments to bring it back to center. This reduces scrap and rework, improves process stability, and lowers overall production costs.

Invest in Comprehensive Training

Your people are your most important quality asset. A well-trained team is essential for executing all the strategies listed above. Training should cover how to operate equipment, but also why quality procedures are in place.

Operators should understand how to read technical drawings, use measurement tools properly, and follow control plans. Inspectors need in-depth knowledge of metrology principles and MSA. You should train engineers and managers in SPC and root cause analysis. Continuous training keeps skills sharp and reinforces the importance of a quality-first culture throughout the organization.

Manage Supplier Quality

Your quality is tied to the quality of the raw materials and components you receive from suppliers. A robust supplier quality management program is crucial. This begins with a rigorous supplier qualification process to vet potential partners.

Establish clear quality requirements and specifications for all purchased materials. Implement a receiving inspection process to verify that incoming goods meet these standards. Regularly audit your suppliers and work collaboratively with them to resolve any quality issues. A strong partnership with your suppliers is a key component of end-to-end quality control.

A systematic approach is essential for enhancing product quality and manufacturing efficiency. By integrating these practices, you establish a resilient framework that fosters consistency and minimizes defects. These are proven ways to improve quality control in manufacturing, and their successful implementation drives customer satisfaction and long-term business success.