8/25/25

The Properties of Synthetic Ruby Spheres

If you work with coordinate measuring machines (CMMs), your focus might be on the machine. What you might not realize is that the real magic happens in the styli. Every tactile probe relies on precision, and the synthetic ruby sphere is no exception. The physical and chemical properties of synthetic ruby spheres directly influence the accuracy, repeatability, and lifespan of the styli. From their durability to their smooth and consistent surface, these styli bring serious performance for countless measurements. Explore what makes synthetic ruby special, how it’s used, and how you can maximize its benefits in your operations.

What Are Synthetic Ruby Spheres, Really?

Unlike natural ruby, synthetic ruby isn’t dug out of the earth. It’s lab-grown for precision (believe us—that’s a good thing).

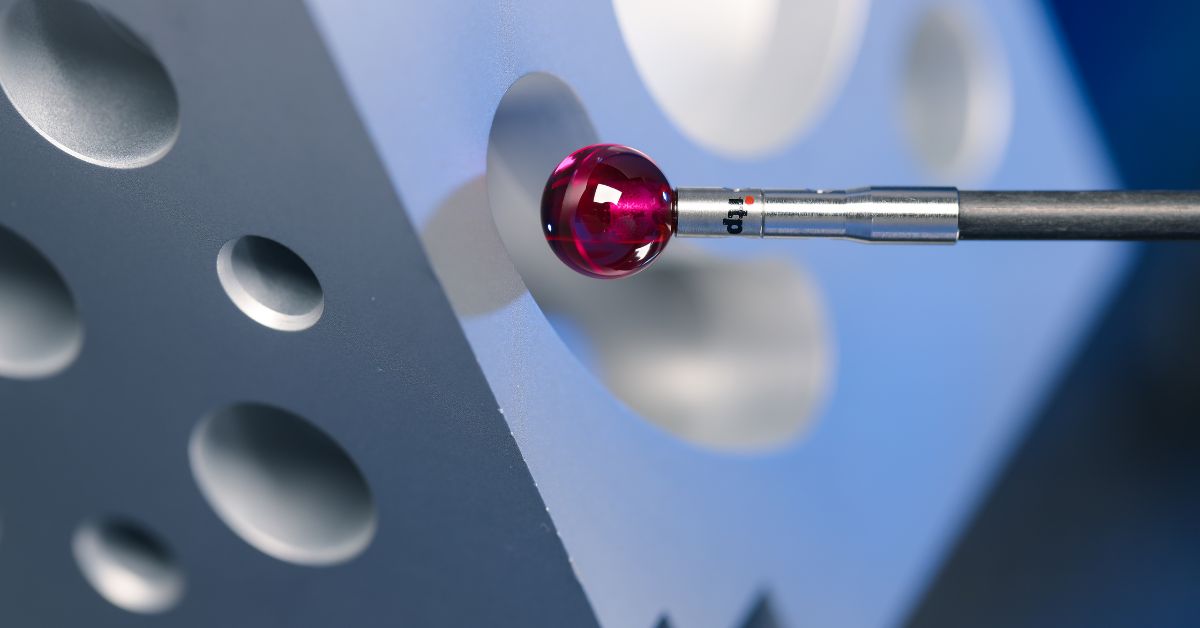

Grown through a controlled process called flame fusion, synthetic ruby is composed of aluminum oxide (Al₂O₃) with trace amounts of chromium. This makeup is what gives the trademark red hue. Every synthetic ruby sphere is virtually identical to the next, which ensures remarkable consistency. This uniformity is key for precise applications, like tactile probing.

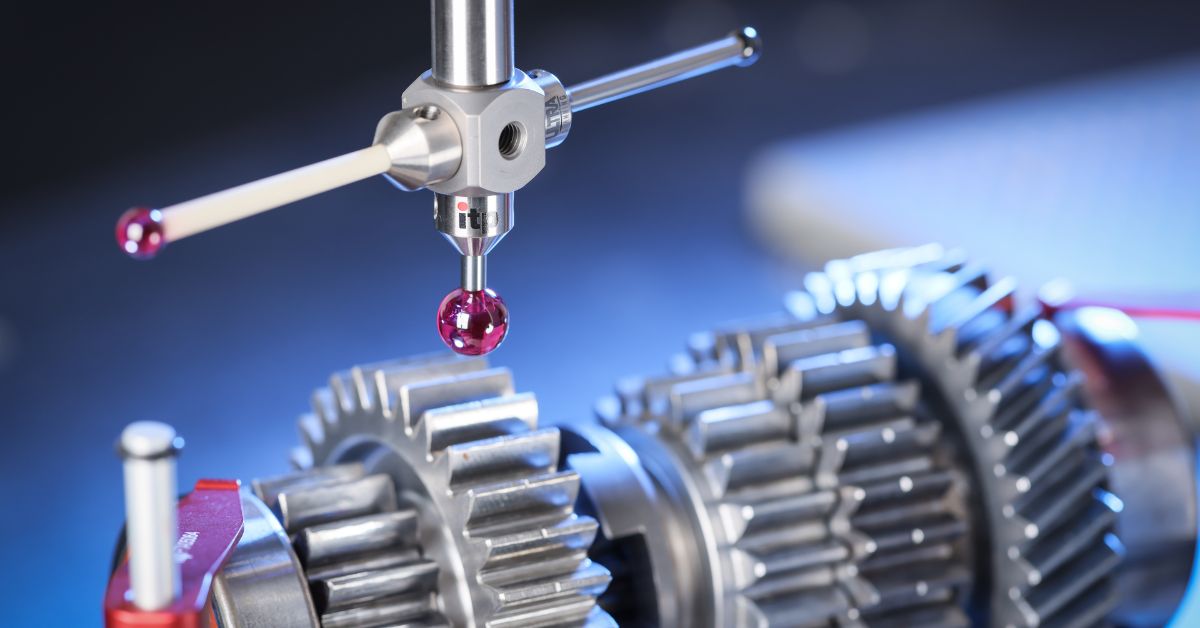

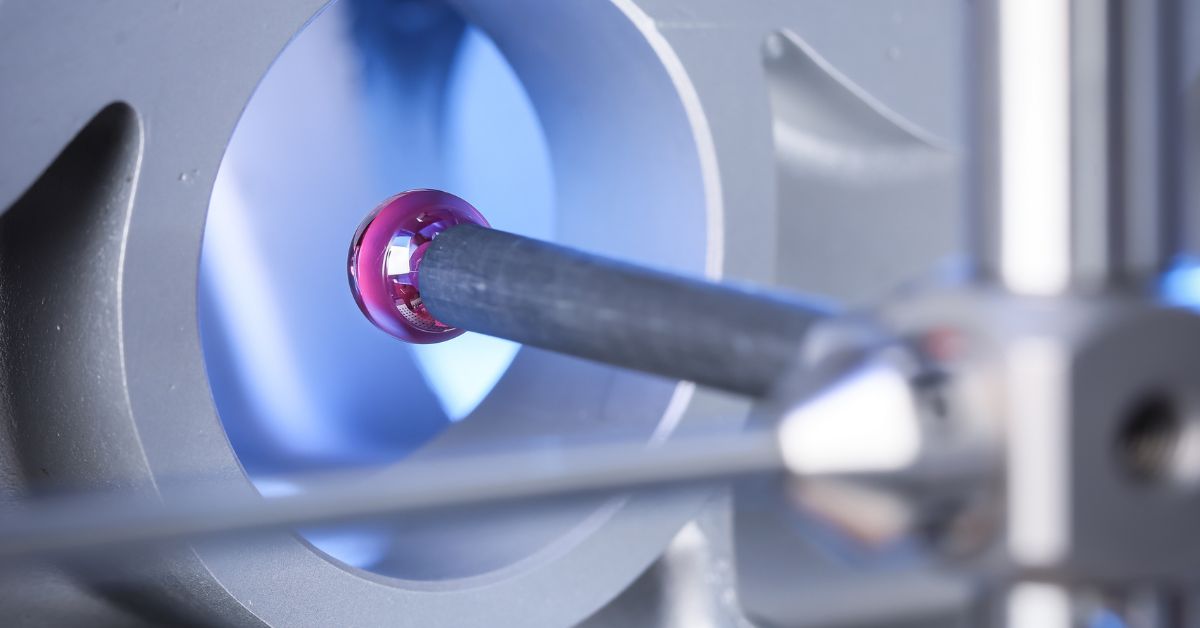

These spheres are mounted on stems to form the tips of styli used in CMMs. During an inspection, the sphere makes contact with a part’s surface to collect data and measurements. The ruby material of the stylus ensures that measurements are precise, stable, and repeatable. This precision is why metrology experts worldwide favor ruby spheres.

Synthetic ruby solves a core issue in measurement technology. It mitigates variables that could compromise accuracy, ensuring fewer surprises and more reliable results.

Key Properties That Make Synthetic Ruby so Effective

Synthetic ruby spheres meet a range of complex demands in modern manufacturing and measurement. Here’s a look at the properties that make them indispensable and how these features translate to real-world benefits.

Extreme Hardness (Mohs 9)

With a Mohs hardness of nine, synthetic ruby is nearly as hard as diamond. This exceptional durability means it can withstand repeated contact with surfaces without wearing down significantly. You can expect a long service life with a ruby ball stylus, especially if you’re working with clean, machined surfaces. Less wear means fewer replacements and more productive uptime.

High Roundness and Smooth Finish

A highly polished, perfectly round ruby sphere ensures minimal friction during contact. This reduces the risk of dragging, surface marking, and measurement inaccuracies. Parts can better meet specifications with this help.

Chemical Inertness

Ruby spheres are chemically stable, making them resistant to corrosion in environments exposed to light caustics or machining oils. This ensures that they will maintain integrity and performance even on a busy shop floor. Never worry about degradation or rust with this material!

Lightweight (Low Mass)

Thanks to their low mass, ruby spheres are ideal for dynamic probing systems. The lightweight design reduces inertia, which improves speed and responsiveness without sacrificing accuracy. High-speed production environments benefit the most from this. Lightweight spheres enable faster measurements while maintaining precision.

Thermal Stability

Temperature fluctuations can be common in a manufacturing environment. Synthetic ruby remains dimensionally stable across a broad range of temperatures. This will ensure consistent measurements regardless of environmental conditions. For high-speed scanning or tactile touch-trigger probes, synthetic ruby is difficult to beat.

Why Manufacturers Choose Synthetic Ruby for CMM Styli

Synthetic ruby’s versatility and proven track record in precision measurement make it indispensable in industries that demand uncompromising accuracy. Beyond its impressive physical properties, what truly sets synthetic ruby apart is the value it adds to manufacturing operations. Consider the following advantages:

- Ruby spheres support high-resolution probing, delivering the repeatability manufacturers need to measure intricate geometries and meet tight tolerances with confidence.

- Reliable ruby styli reduce the need for frequent recalibrations. This saves time and supports smoother, more efficient production flows.

- Working across various CMMs and part materials, these styli are a flexible, long-term solution as equipment and production demands evolve.

- Reliable, spec-accurate measurements are critical to industries like aerospace, automotive, and medical manufacturing. Ruby styli help to ensure compliance with strict standards and customer requirements.

Investing in a synthetic ruby sphere stylus is choosing a solution shaped by precision engineering that seamlessly supports your most critical operations.

When (and Where) Synthetic Ruby Works Best

Synthetic ruby performs exceptionally well in numerous inspection scenarios, but it’s important to understand its strengths and limitations. Here are cases where ruby works best, and where alternatives might be better.

Ideal Applications

- Machined aluminum, stainless steel, and hard plastics.

- Tactile touch-trigger probes and dynamic probing systems.

- Day-to-day shop floor inspections requiring repeatability and precision.

Conditions To Avoid

- Rough or abrasive surfaces like cast iron or carbon fiber. These surfaces can cause rapid wear or pitting that diminishes the sphere’s lifespan and accuracy.

For more abrasive materials, consider alternatives such as silicon nitride or diamond styli. These options are better suited for extreme cases where ruby may fall short.

Best Practices for Ruby Stylus Longevity

To extend the lifespan of a ruby ball stylus and maximize its performance, follow these best practices:

- Dust, oils, and machining debris can accumulate on the ruby ball, compromising its ability to provide accurate measurements. Clean it regularly to remove contamination.

- Avoid crashing or dragging the stylus across surfaces, as this can chip, scratch, or otherwise damage its smooth finish.

- Use magnification tools to periodically inspect the stylus for signs of wear. Replace it if you notice chips, scratches, or a noticeable decrease in measurement accuracy.

These simple steps help you get the most out of your equipment.

Find the Perfect Synthetic Ruby Stylus for Your Needs

Who knew a stylus with a red ball on the end of a probe could provide so much precision, longevity, and reliability? itpstyli knew, and now so do you! The unique properties of synthetic ruby spheres make them an ideal choice for most CMM and metrology applications.

Selecting the right stylus can make all the difference in achieving precise, reliable measurements. With itpstyli’s deep expertise and high-quality synthetic ruby sphere styli, you can trust that you’re investing in solutions designed to elevate your inspection processes. Whether you need standard replacements or customized options, we’ve got you covered.

Explore our range of styli today to see how the right one can improve your results, and reach out to get expert advice tailored to your shop’s unique needs. Bring precision and reliability to your processes with itpstyli’s products—because accurate measurements start with the right partner.