8/12/25

Everything You Need To Know About CMM Metrology

Coordinate measuring machines (CMMs) represent one of the most critical technologies in modern manufacturing quality control. These sophisticated instruments have revolutionized how manufacturers verify dimensional accuracy, ensuring products meet exact specifications across countless industries.

From aerospace components requiring micron-level precision to automotive parts demanding consistent quality, CMM metrology serves as the foundation of reliable manufacturing processes. This comprehensive guide covers everything you need to know about CMM metrology, exploring the technology, applications, and best practices that drive manufacturing excellence.

What Is a Coordinate Measuring Machine (CMM)?

A coordinate measuring machine is a highly accurate tool designed to determine the geometry of physical objects by detecting specific points on their surface with a probe. The machine operates within a three-dimensional coordinate system, typically using X, Y, and Z axes to determine exact positions and dimensions of measured features. CMMs capture data points that software then processes to calculate dimensions, tolerances, and geometric relationships.

The fundamental principle involves a movable probe that contacts or optically measures specific points on a part's surface. Advanced CMM systems can measure complex geometries with exceptional accuracy, often achieving measurement uncertainties within micrometers. This precision makes CMMs indispensable for quality control, reverse engineering, and inspection processes across manufacturing environments.

The Evolution of CMM Metrology

CMM technology has undergone a remarkable transformation since its introduction in the 1960s. Early machines were primarily manual, requiring operators to guide probes to measurement points by hand. These systems, while groundbreaking for their time, were labor-intensive and prone to operator-induced errors.

The introduction of computer numerical control (CNC) capabilities marked a significant advancement that enabled automated measurement routines and improved repeatability. Modern CMMs incorporate sophisticated software, advanced probe technologies, and enhanced environmental controls that deliver unprecedented accuracy and efficiency.

Contemporary CMM systems feature multi-sensor capabilities, allowing single machines to perform tactile, optical, and laser measurements. This evolution has expanded CMM applications beyond traditional dimensional inspection to include surface texture analysis, geometric dimensioning and tolerancing (GD&T) verification, and complex shape measurement.

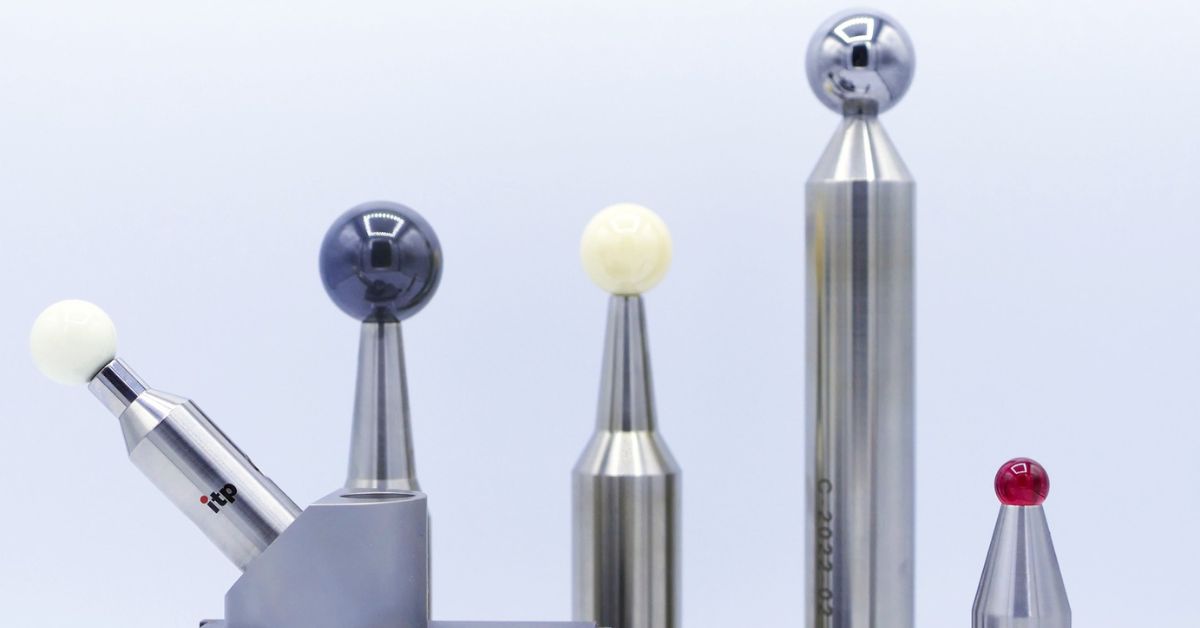

Types of CMM Probes From Itpstyli and Their Applications

CMM probe selection directly impacts measurement accuracy and efficiency. Different probe configurations serve specific measurement requirements, making understanding their applications essential for optimal performance.

Straight Styli

Straight styli are the most common probe configuration, featuring a simple ball tip mounted on a straight stem. These probes excel at measuring external surfaces, holes, and basic geometric features. Their straightforward design provides excellent rigidity and accuracy for routine dimensional measurements.

Star Styli

Star styli incorporate multiple measuring tips arranged in various configurations, enabling measurement of multiple surfaces without probe changes. These probes significantly reduce setup time and improve measurement efficiency when inspecting complex parts with multiple features requiring different approach angles.

Disc Styli

Disc styli feature flat, circular measuring surfaces ideal for measuring thin walls, slots, and recessed features. The disc configuration prevents the probe from falling into grooves or slots during measurement, ensuring consistent contact with intended surfaces.

Cylinder Styli

Cylinder styli utilize cylindrical measuring surfaces that excel at measuring internal features like holes and bores. The extended contact area provides stable measurements of curved surfaces and internal geometries that point contact probes cannot effectively measure.

Custom Styli

Custom styli address unique measurement challenges that standard configurations cannot accommodate. These specialized probes enable access to complex geometries, deep recesses, and intricate features while maintaining measurement accuracy.

Key Benefits of CMM Metrology

CMM metrology delivers substantial advantages that directly impact manufacturing quality and efficiency. Primary benefits include enhanced measurement accuracy, reduced inspection time, and comprehensive documentation capabilities. CMMs eliminate human error associated with manual measurement techniques while providing repeatable, traceable results.

Cost reduction represents another significant advantage, as CMMs identify quality issues early in production processes, preventing costly rework and scrap. The technology permits statistical process control through continuous monitoring of critical dimensions. This supports proactive quality management strategies.

CMMs also support compliance with advanced quality standards, including ISO 9001 and industry-specific requirements. Automated reporting capabilities streamline documentation processes while ensuring complete traceability of measurement results.

Applications of CMM Metrology Across Industries

Aerospace Manufacturing

Aerospace manufacturing demands exceptional precision due to stringent safety requirements and performance specifications. CMMs verify critical dimensions of engine components, structural elements, and flight control systems. The technology ensures compliance with aerospace quality standards while supporting certification processes for new aircraft designs.

Automotive Manufacturing

Automotive manufacturers rely on CMM metrology for engine components, transmission parts, and safety-critical systems. CMMs verify the dimensional accuracy of complex geometries while supporting high-volume production requirements. The technology helps automotive suppliers meet original equipment manufacturer (OEM) specifications consistently.

Medical Devices Manufacturing

Medical device manufacturing requires precise dimensional control to ensure patient safety and device functionality. CMMs verify implant dimensions, surgical instrument accuracy, and diagnostic equipment components. The technology supports FDA compliance requirements while ensuring consistent product quality.

Electronics Manufacturing

Electronics manufacturing utilizes CMM metrology for connector verification, circuit board inspection, and component positioning accuracy. CMMs ensure proper fit and function of miniaturized components while supporting the increasing demands for electronic device miniaturization.

Challenges in CMM Metrology

CMM metrology faces several technical and operational challenges that impact measurement accuracy and efficiency. Environmental factors, including temperature variations, vibration, and humidity, can affect measurement results. Proper environmental control and machine isolation are essential for maintaining accuracy.

Operator skill requirements present another challenge, as CMM programming and operation demand specialized knowledge. Training programs and user-friendly software interfaces help address this challenge, but skilled personnel remain critical for optimal performance.

Part fixturing and accessibility issues can complicate measurement processes, particularly for complex geometries. Careful fixture design and probe selection strategies help overcome these challenges while maintaining measurement accuracy.

Best Practices for Optimizing CMM Performance

Maximizing CMM performance requires attention to multiple factors, including environmental control, regular calibration, and proper maintenance procedures. Temperature stability within measurement environments ensures consistent accuracy, while vibration isolation prevents external disturbances from affecting results.

Regular calibration using certified reference standards maintains measurement traceability and accuracy. Preventive maintenance programs, including probe tip inspection, machine cleaning, and software updates, ensure continued reliable operation.

Operator training and certification programs ensure proper machine utilization while preventing damage from incorrect operation. Documentation of measurement procedures and results supports quality system requirements and continuous improvement initiatives.

CMM metrology is essential for achieving precision and efficiency in many industries, ensuring superior product quality and reduced waste. Now that you’re armed with everything you need to know about CMM technology, you can choose the right tools to optimize your inspection processes and handle even the most complex measurement challenges effectively.

When it comes to styli, Itpstyli stands out as the trusted choice, offering a wide range of high-quality products and unmatched convenience with same-day CMM probe stylus shipping. Don’t settle for less when your business depends on accuracy and reliability. Explore our extensive selection today to elevate your metrology results and stay ahead in your field.