11/19/25

Diamond-Coated vs. Solid Diamond: What To Know

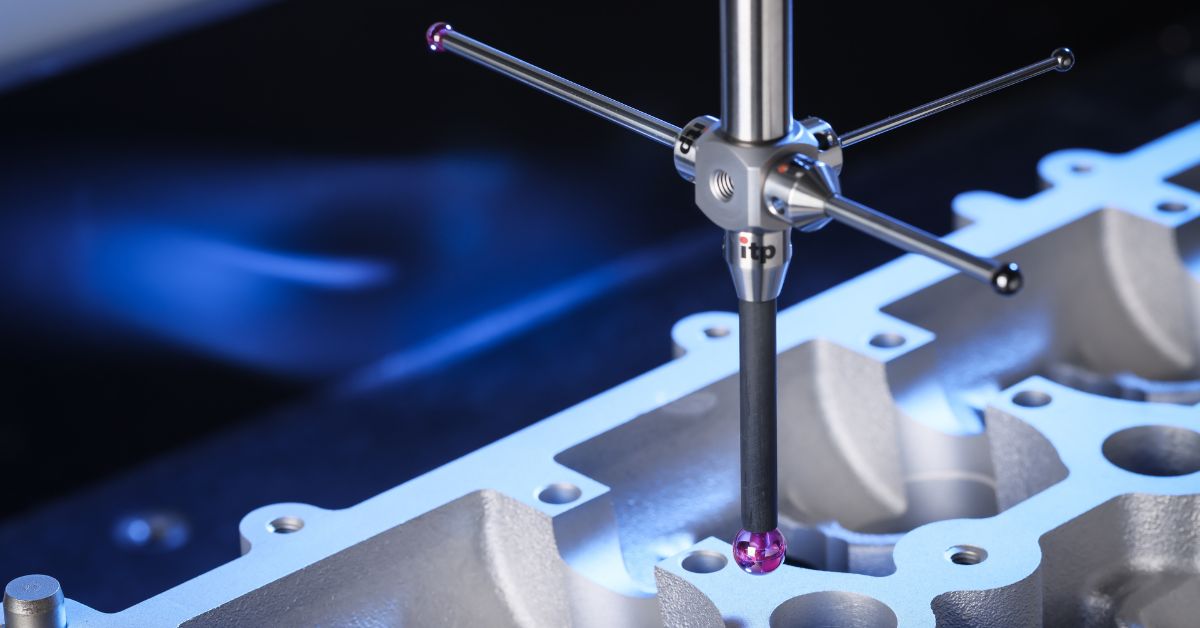

In precision measurement, every detail carries significance, right down to the smallest part. The stylus tip, which makes contact with the workpiece, can directly shape results and even influence your bottom line.

Its material, shape, and durability consistently impact both accuracy and confidence in your process. If your team deals with abrasive surfaces or works through high-volume scanning routines, the composition of your stylus tip becomes a matter of lasting reliability. That’s why it pays to examine what to know about diamond-coated and solid diamond styli before making a purchase decision.

Understanding the Role of a Stylus Tip

Before discussing diamond technology, let’s look at what a stylus tip actually does. This precision component sits on the end of the stylus shaft. It is the very first point of contact between your CMM, gear measurement, or machine tool system and the objects you’re measuring.

Accuracy hinges on the tip’s integrity. If it isn’t perfectly spherical or starts to show surface wear, it can compromise your measurement data. Even small surface imperfections or contamination can influence outcomes. This is especially true as tolerances tighten in various industrial and manufacturing landscapes.

For most users, materials like ruby or silicon nitride often serve well. However, with challenging surfaces, like rough castings, hard ceramics, or fiber-reinforced composites, these standard tips may wear down too quickly. In such cases, diamond options become a practical consideration.

What Are Diamond-Coated Styli?

Diamond-coated styli combine two strengths. The tip has a strong ceramic core (most commonly silicon carbide) surrounded by a very thin, uniform industrial diamond layer. Advanced coating techniques permanently bond this layer to the substrate.

The goal is to combine the renowned durability of diamond with the strength and reliability of a modern base material. This design lets you achieve exceptional wear resistance without taking on the fragility, cost, or limitations of a solid diamond tip.

If you’re involved in continuous scanning, especially on rough, high-volume parts, a diamond-coated stylus will likely protect your process and limit unplanned downtime.

The Advantages of Diamond-Coated Styli

Manufacturers in the aerospace, medical, and electronics sectors routinely encounter situations where diamond-coated tips enhance precision and uptime.

Below are the key advantages of this solution:

Superior Wear Resistance

Diamond, as the hardest natural substance, stands up to abrasive forces. That means when you’ve got challenging surfaces like cast iron or composite materials, the tip keeps its shape for vastly longer periods than ruby. This, in turn, leads to fewer stylus replacements and schedule interruptions.

Regular users of this styli will notice the time it saves. Longevity directly reduces the need for frequent recalibration and minimizes machine downtime. All in all, diamond-coating ensures operational continuity.

Improved Scanning Results

The unique hardness and polished surface of diamond-coated styli drastically reduce friction and unwanted material transfer. This is crucial during continuous scanning, where adhesive wear (tiny particles of the part sticking to a softer tip) can degrade quality.

For example, when scanning an aluminum part with a standard ruby tip, bits of aluminum may accumulate on the tip. This subtle contamination changes the stylus profile and reduces accuracy. By contrast, a diamond surface resists this buildup, strengthening the fidelity of your inspection data.

Value Over Time

Upfront, diamond-coated styli often cost more than their ruby counterparts. Yet for users who deal with abrasive processes, the investment can be strategic. Frequent replacement of worn ruby tips, coupled with lost productivity, adds up.

Switching to diamond-coated tips helps mitigate these costs. In many cases, the reduction in slowdowns and replacement expenses justifies the decision. As a result, for applications where tip wear is a persistent pain point, diamond-coated styli help control operational budgets.

What About Solid Diamond Styli?

To frame the comparison, it’s helpful to know what differentiates solid diamond from diamond coating.

Solid diamond styli are crafted, often in very small sizes, from one continuous piece of industrial diamond. This makes them exceptionally hard and almost impervious to wear.

However, there are important trade-offs to note:

- Solid diamond tips are extremely brittle. Their hardness means they can fracture if subjected to an abrupt impact or heavy side-load.

- They’re costly. The process of manufacturing a single-crystal diamond ball is difficult and resource-intensive, limiting its size and affordability.

- Due to cost and fragility, solid diamond styli are mainly used in unique scenarios. This includes micro-measurement tasks or when part geometry demands the tiniest possible tip.

Most industrial scanning or CMM tasks are better handled with diamond-coated styli rather than solid diamond, offering dependable durability without financial and operational risks.

Maintaining Your Diamond-Coated Styli

Even the most durable solutions require care. By maintaining your diamond-coated styli, you prolong their life and performance, ensuring you get the most from your investment.

Here are the best practices that support reliability:

- Routine inspection: Use a magnifier to check tips for signs of damage or debris accumulation.

- Gentle cleaning: Even with the diamond’s non-stick qualities, occasional cleaning is worthwhile. Use approved putty or a lint-free cloth with a specialized solution to remove contaminants.

- Careful handling: Collisions from accidental drops or misaligned setups can still damage the tip or mounting. Handle probes thoughtfully throughout setup, storage, and operation.

- Preventing unnecessary impact: Program machines with caution, particularly if using long styli on complex features.

By following these straightforward guidelines, you can safeguard the integrity of your stylus tips and help them achieve their expected lifespan.

Why itpstyli Is the Right Choice for Your Needs

At itpstyli, our inventory emphasizes premium diamond-coated styli made to deliver consistent performance in the most challenging measurement environments. We understand the specific demands of CMM, machine tool, and gear measurement, and we’re committed to helping you find exactly what you need—quickly, clearly, and reliably.

Our experienced team provides personalized recommendations so you always select the ideal stylus for your application. We stand behind every product in our catalog, prioritizing your satisfaction, productivity, and peace of mind.

Choosing the best stylus supports more than measurement accuracy. It underpins your entire production process, optimizing efficiency, reducing long-term costs, and helping your business deliver on the highest standards of quality.

Selecting the right stylus starts with understanding your specific measurement challenges. If minimizing wear, maximizing accuracy, and reducing maintenance interruptions are your priority, diamond-coated styli represent a practical, durable, and cost-effective investment for most advanced CMM operations. That’s what to know about diamond-coated and solid diamond styli.

Have a challenging surface or scan path? Talk with itpstyli about diamond-coated options tailored to your application.