8/21/25

Contact vs. Non-Contact CMM Measurement Methods

The right measurement approach can make or break precision, efficiency, and cost in manufacturing. Therefore, choosing the right approach for your industry is crucial for ensuring quality. Coordinate measuring machines (CMMs) are indispensable for maintaining standards, but the decision between contact and non-contact CMM measurement methods can greatly influence accuracy, cycle times, and costs.

By understanding the unique strengths of each method, engineers and quality control professionals can select a solution that aligns with their materials, tolerances, and budget. Break down the key differences, benefits, and best uses of each measurement technique to find the ideal solution for your needs.

What Is Contact CMM Measurement and How Does It Work?

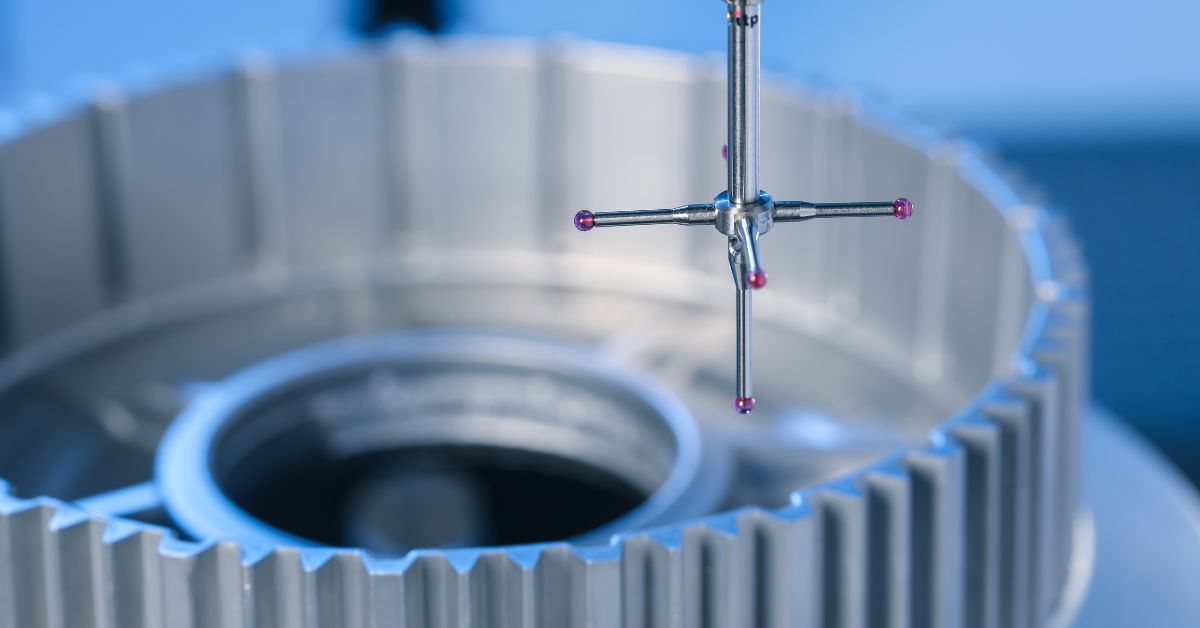

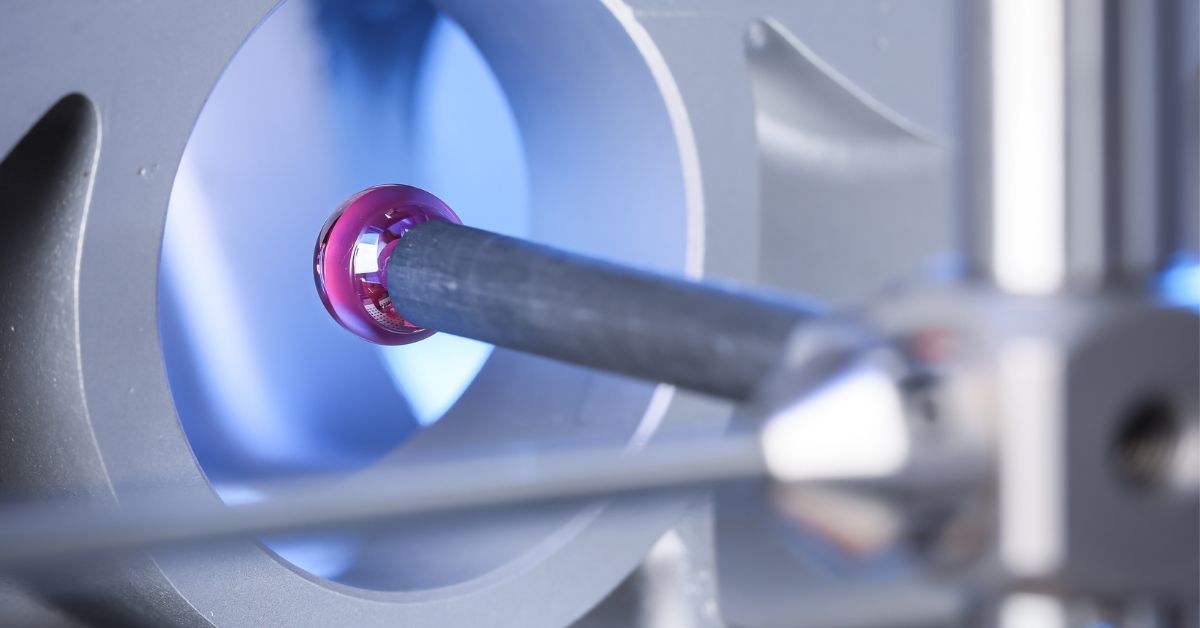

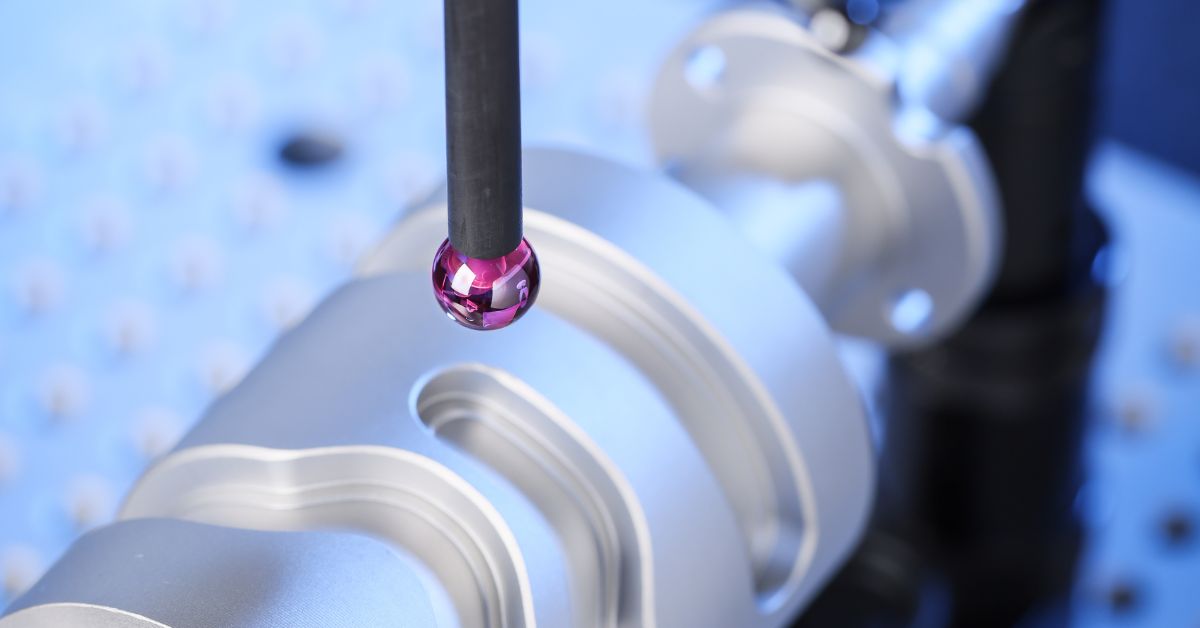

Contact CMM measurement uses physical probes to touch the surface of a workpiece and collect dimensional data. The system relies on precision-engineered styli that make controlled contact with specific points, transmitting position information to the CMM software.

This process enables the machine to calculate coordinates and determine geometric features like circles, planes, and contours. Advanced probe systems ensure accuracy by compensating for stylus geometry and approach angles.

Why Choose Contact CMM Measurement?

Contact measurement is ideal for applications requiring high accuracy and traceability to international standards. Its physical contact eliminates ambiguity, making it ideal for rigid materials and defined surfaces. Professionals in the aerospace, automotive, and medical manufacturing industries rely on contact CMMs for dimensions and regulatory compliance.

Advantages of Contact CMMs

- Exceptional accuracy, often below one micrometer.

- Compatibility with extensive software and standardized procedures.

- Cost-effective compared to non-contact systems.

- Works on surfaces regardless of finish, color, or transparency.

- Access to complex internal geometries with specialized probes.

- Repeatability for statistical process control.

Limitations of Contact CMMs

- Slow measurement speeds due to probe positioning and contact verification.

- Limited effectiveness for fragile components or soft materials prone to deformation.

- Risk of surface damage on delicate finishes or coatings.

- Requires physical access to all measurement points, which can be challenging for complex features.

- Stylus wear over time necessitates replacement and recalibration.

What Is Non-Contact CMM Measurement and How Does It Work?

Non-contact CMM measurement uses lasers, cameras, or structured light to gather dimensional data without touching the surface. It works by projecting energy onto the workpiece and analyzing reflections to calculate coordinates and surface profiles. This approach preserves delicate materials and captures large amounts of data quickly.

The system scans the surface by projecting beams and measuring the reflected signal to create accurate geometry data. Common techniques, such as laser triangulation or structured light, enable the collection of thousands of points in seconds, despite environmental factors.

Why Choose Non-Contact CMM Measurement?

Non-contact methods are ideal when rapid inspection, complex geometries, or surface preservation matter for your project. They are particularly effective for high-volume production workflows, freeform surfaces, or materials too delicate for physical probes. Professionals in electronics, medical devices, and consumer products benefit from the speed and precision these systems provide.

Advantages of Non-Contact CMMs

- Fast scanning speeds for capturing entire surface profiles.

- No risk of damage to soft, fragile, or sensitive materials.

- Handles complex shapes and intricate features with ease.

- Supports real-time inspections in production environments.

- Offers high data density for thorough surface analysis.

Limitations of Non-Contact CMMs

- Less effective on reflective, transparent, or dark surfaces.

- Susceptible to vibrations and environmental factors.

- Higher equipment and operating costs.

- Requires clear visibility of the measurement area.

- May not match the precision of contact systems for tight tolerances.

How To Choose the Right CMM Method for Your Project

Define Your Measurement Goals

Begin by establishing accuracy requirements, measurement features, and quality standards. Dimensions requiring traceability to national standards work well with contact measurement, while comprehensive surface analysis benefits from non-contact approaches.

Consider Material Properties

Evaluate workpiece hardness, surface finish, and fragility. Hard materials with good surface access suit contact measurement, while soft, delicate, or highly complex geometries require non-contact solutions.

Measure Environmental Factors

Take into account environmental conditions, such as vibration, temperature changes, or airborne particles. For environments prone to these challenges, systems or enclosures can support measurement accuracy.

Evaluate Budget Constraints

Consider initial equipment costs and ongoing operational expenses. Contact systems generally require lower initial investment but may operate more slowly, affecting throughput costs. Non-contact systems demand higher upfront investment but can reduce inspection cycle times.

Think About Future Needs

Anticipate evolving measurement requirements, production volumes, and technology trends. Flexible systems that accommodate both contact and non-contact capabilities provide adaptability for changing manufacturing demands.

Real-World Applications and Examples

CMM methods provide precise measurement solutions that meet the needs of professionals in countless industries. Here are some examples of how contact and non-contact systems work in different fields:

- Heavy machinery: Contact CMMs ensure accuracy for large, rigid components like gears, shafts, and bearings.

- Textile industry: Non-contact systems measure fabric dimensions and patterns without causing distortion.

- Energy sector: Contact methods verify turbine part precision, while non-contact systems analyze delicate components like solar panels.

- Research and development: Lab workers use both methods to prototype designs and test materials with unique geometries.

- Jewelry and luxury goods: Non-contact systems inspect intricate designs for projects requiring precision and surface preservation.

Emerging Trends in CMM Technology

Modern CMM systems may integrate both contact and non-contact capabilities on a single platform. Multi-sensor systems enable automatic method selection based on measurement requirements, which optimizes accuracy and efficiency for diverse inspection tasks.

Artificial intelligence and machine learning algorithms enhance measurement planning, reduce operator dependency, and improve measurement uncertainty estimation. These developments make contact and non-contact CMM measurement methods more accessible to manufacturers seeking precision measurement solutions.

Making the right choice in measurement tools can transform your operations to deliver the accuracy and reliability your industry demands. With itpstyli, you gain access to customized precision styli for metrology that will enhance your processes and meet your unique challenges. We provide dependable solutions tailored to your needs!

Understanding the complexities of contact versus non-contact CMM measurement methods is essential for choosing the right solution for your operations. Elevate your measurement capabilities today, and achieve the precision your operations deserve with itpstyli products. Speak with one of our professionals if you have questions about what will work best for your applications.